Specs/CAD

Select

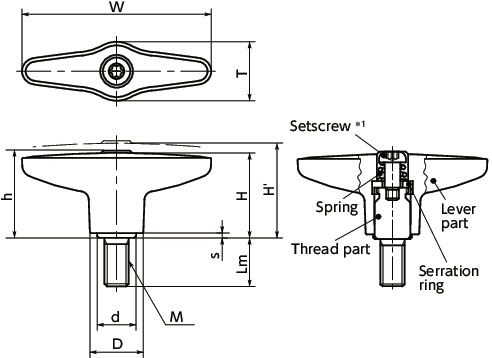

Unit : mm

| Part Number | M (Coarse) Nominal of Thread |

Pitch | Lm | W | H | H' | h | s | T | D | d | Tooth No. | Max. load*1 (N) |

Max. tightening force*1 (kN) |

Lever Part Color |

Mass (g) |

CAD Download |

Cart |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LUDM-78-10-16-SG | M10 | 1.5 | 16 | 78 | 35 | 39 | 36 | 2 | 24.3 | 22 | 16 | 26 | 390 | 11 | SG | 66 | CAD | RFQ |

| LUDM-78-10-16-YW | M10 | 1.5 | 16 | 78 | 35 | 39 | 36 | 2 | 24.3 | 22 | 16 | 26 | 390 | 11 | YW | 66 | CAD | RFQ |

| LUDM-78-10-16-BK | M10 | 1.5 | 16 | 78 | 35 | 39 | 36 | 2 | 24.3 | 22 | 16 | 26 | 390 | 11 | BK | 66 | CAD | RFQ |

| LUDM-78-10-16-BL | M10 | 1.5 | 16 | 78 | 35 | 39 | 36 | 2 | 24.3 | 22 | 16 | 26 | 390 | 11 | BL | 66 | CAD | RFQ |

| LUDM-78-10-16-OR | M10 | 1.5 | 16 | 78 | 35 | 39 | 36 | 2 | 24.3 | 22 | 16 | 26 | 390 | 11 | OR | 66 | CAD | RFQ |

| LUDM-78-10-20-SG | M10 | 1.5 | 20 | 78 | 35 | 39 | 36 | 2 | 24.3 | 22 | 16 | 26 | 390 | 11 | SG | 67 | CAD | RFQ |

| LUDM-78-10-20-YW | M10 | 1.5 | 20 | 78 | 35 | 39 | 36 | 2 | 24.3 | 22 | 16 | 26 | 390 | 11 | YW | 67 | CAD | RFQ |

| LUDM-78-10-20-BK | M10 | 1.5 | 20 | 78 | 35 | 39 | 36 | 2 | 24.3 | 22 | 16 | 26 | 390 | 11 | BK | 67 | CAD | RFQ |

| LUDM-78-10-20-BL | M10 | 1.5 | 20 | 78 | 35 | 39 | 36 | 2 | 24.3 | 22 | 16 | 26 | 390 | 11 | BL | 67 | CAD | RFQ |

| LUDM-78-10-20-OR | M10 | 1.5 | 20 | 78 | 35 | 39 | 36 | 2 | 24.3 | 22 | 16 | 26 | 390 | 11 | OR | 67 | CAD | RFQ |

| LUDM-78-10-25-SG | M10 | 1.5 | 25 | 78 | 35 | 39 | 36 | 2 | 24.3 | 22 | 16 | 26 | 390 | 11 | SG | 70 | CAD | RFQ |

| LUDM-78-10-25-YW | M10 | 1.5 | 25 | 78 | 35 | 39 | 36 | 2 | 24.3 | 22 | 16 | 26 | 390 | 11 | YW | 70 | CAD | RFQ |

| LUDM-78-10-25-BK | M10 | 1.5 | 25 | 78 | 35 | 39 | 36 | 2 | 24.3 | 22 | 16 | 26 | 390 | 11 | BK | 70 | CAD | RFQ |

| LUDM-78-10-25-BL | M10 | 1.5 | 25 | 78 | 35 | 39 | 36 | 2 | 24.3 | 22 | 16 | 26 | 390 | 11 | BL | 70 | CAD | RFQ |

| LUDM-78-10-25-OR | M10 | 1.5 | 25 | 78 | 35 | 39 | 36 | 2 | 24.3 | 22 | 16 | 26 | 390 | 11 | OR | 70 | CAD | RFQ |

| LUDM-78-10-32-SG | M10 | 1.5 | 32 | 78 | 35 | 39 | 36 | 2 | 24.3 | 22 | 16 | 26 | 390 | 11 | SG | 73 | CAD | RFQ |

| LUDM-78-10-32-YW | M10 | 1.5 | 32 | 78 | 35 | 39 | 36 | 2 | 24.3 | 22 | 16 | 26 | 390 | 11 | YW | 73 | CAD | RFQ |

| LUDM-78-10-32-BK | M10 | 1.5 | 32 | 78 | 35 | 39 | 36 | 2 | 24.3 | 22 | 16 | 26 | 390 | 11 | BK | 73 | CAD | RFQ |

| LUDM-78-10-32-BL | M10 | 1.5 | 32 | 78 | 35 | 39 | 36 | 2 | 24.3 | 22 | 16 | 26 | 390 | 11 | BL | 73 | CAD | RFQ |

| LUDM-78-10-32-OR | M10 | 1.5 | 32 | 78 | 35 | 39 | 36 | 2 | 24.3 | 22 | 16 | 26 | 390 | 11 | OR | 73 | CAD | RFQ |

| LUDM-78-10-40-SG | M10 | 1.5 | 40 | 78 | 35 | 39 | 36 | 2 | 24.3 | 22 | 16 | 26 | 390 | 11 | SG | 77 | CAD | RFQ |

| LUDM-78-10-40-YW | M10 | 1.5 | 40 | 78 | 35 | 39 | 36 | 2 | 24.3 | 22 | 16 | 26 | 390 | 11 | YW | 77 | CAD | RFQ |

| LUDM-78-10-40-BK | M10 | 1.5 | 40 | 78 | 35 | 39 | 36 | 2 | 24.3 | 22 | 16 | 26 | 390 | 11 | BK | 77 | CAD | RFQ |

| LUDM-78-10-40-BL | M10 | 1.5 | 40 | 78 | 35 | 39 | 36 | 2 | 24.3 | 22 | 16 | 26 | 390 | 11 | BL | 77 | CAD | RFQ |

| LUDM-78-10-40-OR | M10 | 1.5 | 40 | 78 | 35 | 39 | 36 | 2 | 24.3 | 22 | 16 | 26 | 390 | 11 | OR | 77 | CAD | RFQ |

| LUDM-78-10-50-SG | M10 | 1.5 | 50 | 78 | 35 | 39 | 36 | 2 | 24.3 | 22 | 16 | 26 | 390 | 11 | SG | 82 | CAD | RFQ |

| LUDM-78-10-50-YW | M10 | 1.5 | 50 | 78 | 35 | 39 | 36 | 2 | 24.3 | 22 | 16 | 26 | 390 | 11 | YW | 82 | CAD | RFQ |

| LUDM-78-10-50-BK | M10 | 1.5 | 50 | 78 | 35 | 39 | 36 | 2 | 24.3 | 22 | 16 | 26 | 390 | 11 | BK | 82 | CAD | RFQ |

| LUDM-78-10-50-BL | M10 | 1.5 | 50 | 78 | 35 | 39 | 36 | 2 | 24.3 | 22 | 16 | 26 | 390 | 11 | BL | 82 | CAD | RFQ |

| LUDM-78-10-50-OR | M10 | 1.5 | 50 | 78 | 35 | 39 | 36 | 2 | 24.3 | 22 | 16 | 26 | 390 | 11 | OR | 82 | CAD | RFQ |

| LUDM-78-10-63-SG | M10 | 1.5 | 63 | 78 | 35 | 39 | 36 | 2 | 24.3 | 22 | 16 | 26 | 390 | 11 | SG | 89 | CAD | RFQ |

| LUDM-78-10-63-YW | M10 | 1.5 | 63 | 78 | 35 | 39 | 36 | 2 | 24.3 | 22 | 16 | 26 | 390 | 11 | YW | 89 | CAD | RFQ |

| LUDM-78-10-63-BK | M10 | 1.5 | 63 | 78 | 35 | 39 | 36 | 2 | 24.3 | 22 | 16 | 26 | 390 | 11 | BK | 89 | CAD | RFQ |

| LUDM-78-10-63-BL | M10 | 1.5 | 63 | 78 | 35 | 39 | 36 | 2 | 24.3 | 22 | 16 | 26 | 390 | 11 | BL | 89 | CAD | RFQ |

| LUDM-78-10-63-OR | M10 | 1.5 | 63 | 78 | 35 | 39 | 36 | 2 | 24.3 | 22 | 16 | 26 | 390 | 11 | OR | 89 | CAD | RFQ |

| LUDM-78-10-80-SG | M10 | 1.5 | 80 | 78 | 35 | 39 | 36 | 2 | 24.3 | 22 | 16 | 26 | 390 | 11 | SG | 97 | CAD | RFQ |

| LUDM-78-10-80-YW | M10 | 1.5 | 80 | 78 | 35 | 39 | 36 | 2 | 24.3 | 22 | 16 | 26 | 390 | 11 | YW | 97 | CAD | RFQ |

| LUDM-78-10-80-BK | M10 | 1.5 | 80 | 78 | 35 | 39 | 36 | 2 | 24.3 | 22 | 16 | 26 | 390 | 11 | BK | 97 | CAD | RFQ |

| LUDM-78-10-80-BL | M10 | 1.5 | 80 | 78 | 35 | 39 | 36 | 2 | 24.3 | 22 | 16 | 26 | 390 | 11 | BL | 97 | CAD | RFQ |

| LUDM-78-10-80-OR | M10 | 1.5 | 80 | 78 | 35 | 39 | 36 | 2 | 24.3 | 22 | 16 | 26 | 390 | 11 | OR | 97 | CAD | RFQ |

*1: For the definitions of maximum load and maximum clamping force, see "Using the Clamp Lever / Tension Lever."⇒Using the Clamp Lever / Tension Lever

Nabeya Bi-tech Kaisha

Customer Service

Please enter questions about customization and other product-related inquiries here.

Find the inquiry form hereMaterial/Finish

| LUDM | |

|---|---|

| Lever Part | Nylon 6 (Various Color) |

| Thread Part | SUM22L Ferrosoferric Oxide Film (Black) |

| Setscrew | Steel Ferrosoferric Oxide Film (Black) |

| Serration Ring | Zinc Die Cast |

| Spring | Stainless Steel Wire or SWPB |

Characteristics

- A double arm type clamp lever made of plastic.

- Designed in consideration of the seven principles of universal design. A shape for easy application of forces and operations.

- About Universal Design ⇒Universal design UDEX® series

- The rotating radius is about a half of plastic clamp levers. Space-saving.

- A serration ring made of zinc die cast is inserted into the lever body made of plastic. They also realize sufficient strength for fitting with metal thread serration.

-

There are two types of thread part materials:

LUDM----Made of steel

LUDMS----Made of stainless steel - A rich variety of thread sizes from M3 to M12 are available.

- Five-color variations support the color universal design of machines / devices. Two-tone color of dark gray and various colors.

- Lever part colors can be selected by the end symbol of the part number.

| End Symbol | Lever Part Color |

|---|---|

| BK | Matte black |

| SG | Matte Silver |

| OR | Matte orange |

| BL | Matte blue |

| YW | Matte yellow |

Only takes a minute to understand! How to Use Clamp Levers.

Related Products

SWAS-PPK washers suitable for positioning and fixing slide mechanisms using slotted holes are available. SWAS-PPK