Specs/CAD

| Part Number | Max. Allowable Load *1 (N) |

Mass (g) |

Cover Color | CAD Download |

Cart |

|---|---|---|---|---|---|

| UPVF-3NC-BK | 500 | 167 | BK | CAD | RFQ |

| UPVF-3NC-BL | 500 | 167 | BL | CAD | RFQ |

| UPVF-3NC-SG | 500 | 167 | SG | CAD | RFQ |

*1: Allowed load for a person.

Nabeya Bi-tech Kaisha

Customer Service

Please enter questions about customization and other product-related inquiries here.

Find the inquiry form hereMaterial/Finish

| UPVF | |

|---|---|

| Main Body | Glass Fiber Reinforced Nylon 6 |

| Push Button | Aluminum Alloy Anodized |

| Cover | Aluminum Alloy Anodized (Various Colors) |

| Pneumatic Valve | PBT Brass Electroless Nickel Plating |

| Thread Part | Steel Trivalent Chromate Treatment |

Characteristics

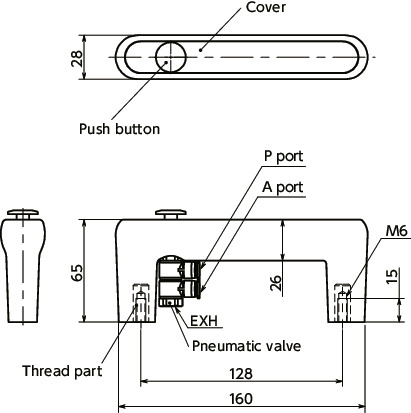

- These plastic pulls have 2-position, 3-way pneumatic valves mounted.

- A φ6 fitting is included with the pneumatic valve.

- The spool valve mechanism keeps the button operation unaffected by pressure.

- When the push button is released, it returns to its original position through built-in spring force.

- Cover colors can be selected by the end symbol of the part number.

| End Symbol | Cover Color |

|---|---|

| BK | Anodized (Black) |

| BL | Anodized (Blue*1) |

| SG | Anodized (Silver) |

*1: Due to the use of colored anodizing, color fluctuations may appear.

Specifications

| Activation Type | Normally Closed |

| Min. Operating Pressure | 0MPa |

| Max. Operating Pressure | 0.7MPa |

| Operating Temperature | 0°C to 50°C (no freezing) |

| Applicable Tube O.D. | φ6 |

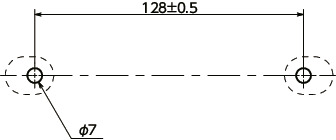

Mounting hole

Errors may appear in the mounting dimensions due to temperature or humidity.Press against the mounting surface and align the pitch to mount.

Precautions for Use

Improper handling of pneumatic devices is dangerous. Machinery and equipment using pneumatic devices should be assembled and maintained by personnel with sufficient knowledge and experience.Tube Mounting and Removing Methods

Tube Mounting

The tube is fixed by being fully inserted*1.After fixing, check that the tube does not come out when pulled.

*1: Leaks may occur if the tube is not fully inserted.

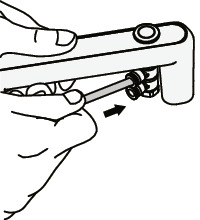

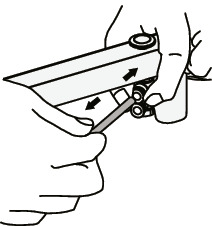

Tube Removing

Confirm that the tube internal pressure is zero.Push the fitting release ring evenly inward*1 and pull the tube out forward.

*1: If not pushed far enough in, the tube may not come out or may be scratched.

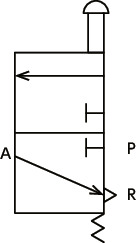

JIS Symbol