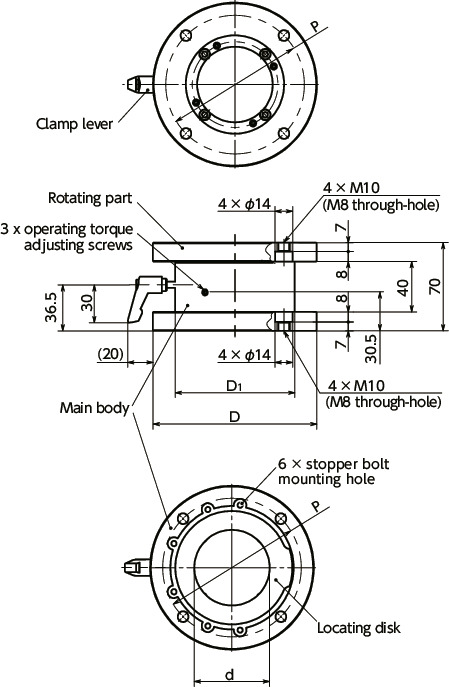

Specs/CAD

Unit : mm

| Part Number | D | D1 | d | P | Max. Load Weight (kg) |

Allowable Moment*1 (N・m) |

Retention Torque*2 (N・m) |

Mass (g) |

CAD Download |

Cart |

|---|---|---|---|---|---|---|---|---|---|---|

| DKSF-115-45 | 115 | 80 | 45 | 95 | 100 | 200 | 30 | 2580 | CAD | RFQ |

| DKSF-130-60 | 130 | 95 | 60 | 110 | 100 | 315 | 30 | 3130 | CAD | RFQ |

*1: Allowable value for the eccentric load received from the control panel mounted on the rotating part or main body.

*2: Retention torque is the reference maximum retention torque generated when tightening the clamp lever at the maximum clamping force (3.9kN) with no control panel mounted. The retention torque fluctuates in accordance with the tightening strength.

Two stopper bolts are provided.

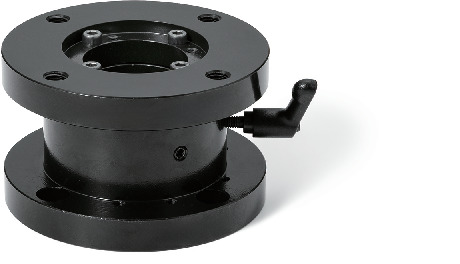

Material/Finish

| DKSF | |

|---|---|

| Main Body | Cast Iron Cathodic Electrodeposition Coating (Black) |

| Rotating part | Cast Iron Cathodic Electrodeposition Coating (Black) |

| Locating Disk | Cast Iron Cathodic Electrodeposition Coating (Black) |

| Clamp Lever | Zinc Die Cast Electrostatic Coating (Matte Black) |

| Operating Torque Adjusting Screw | Steel Ferrosoferric Oxide Film (Black), Nylon Patch (Nylon 11) |

| Stopper Bolt M5 × 8 |

Steel Ferrosoferric Oxide Film (Black) |

Characteristics

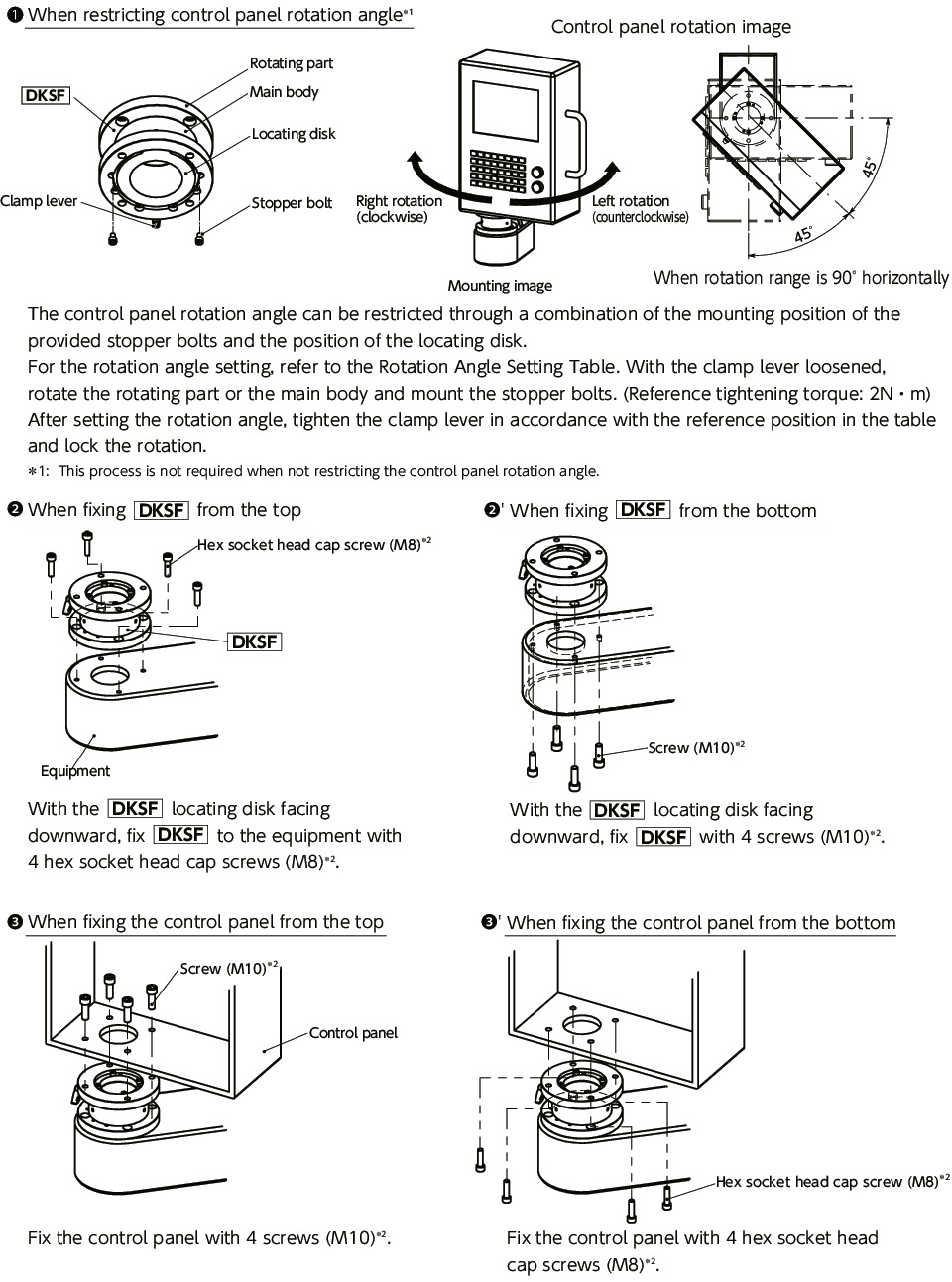

- Unit used to fix and rotate control panels for machine tools, etc.

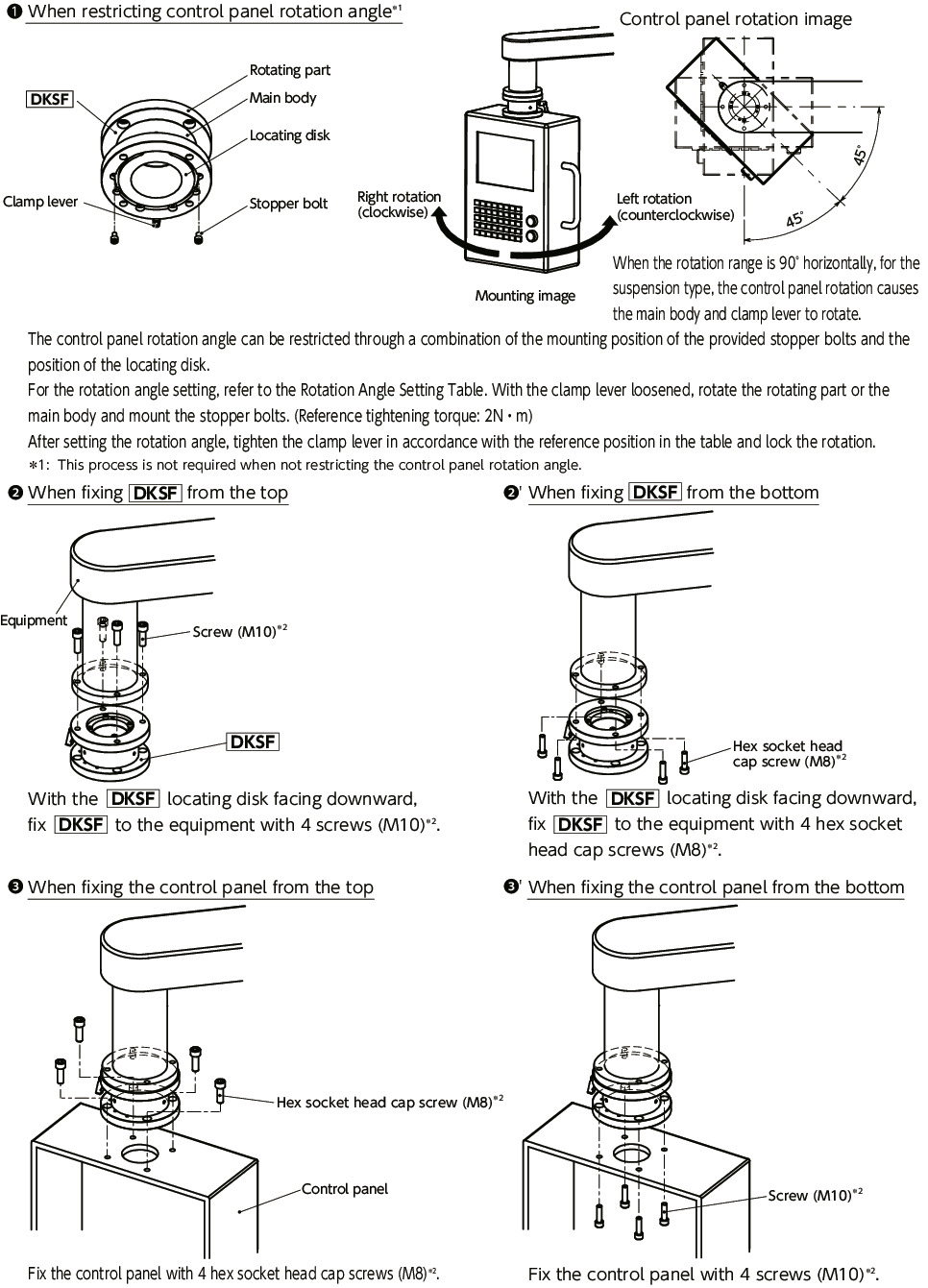

- A single DKSF unit can be used either as a post type with the control panel mounted on the top or as a suspension type with the panel mounted on the bottom.

- The flange mounting holes on the rotating part and main body enable mounting from either top or bottom. Use along with the device/equipment on which the panel is to be mounted.

- Control panel wiring can be passed through from the DKSF central hole.

- Tightening the clamp lever will lock the control panel rotation.

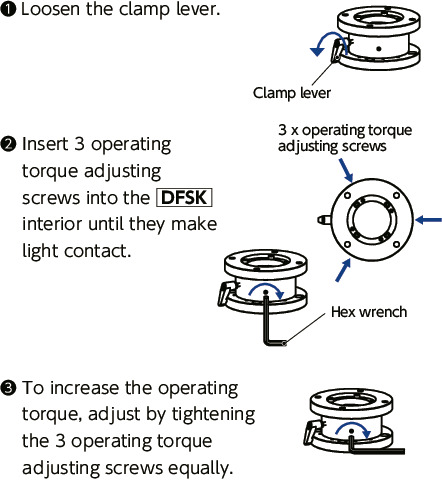

- Tighten the 3 operating torque adjusting screws equally to adjust the operating torque.

-

Mount the included stopper bolts at an arbitrary position on the DKSF bottom to restrict the locating disk rotation angle and set the control panel rotation angle.

The rotation angle can be set within a range of 45° to 360°. For details, refer to the Rotation Angle Setting Table.

Precautions for Use

- When rotating the control panel, move it slowly so as not to apply impact to the stopper bolts. The stopper bolts may break under large impact, making it impossible to restrict the control panel rotation angle.

- When rotating the control panel, check that no one is in its vicinity. Injuries may occur if the control panel makes contact with persons nearby.

- When not using the stopper bolts, the control panel rotation will be unrestricted. Be careful not to twist the wiring.

- Do not rotate screws other than the operating torque adjusting screws and stopper bolts. DKSF may be damaged if screws are rotated.

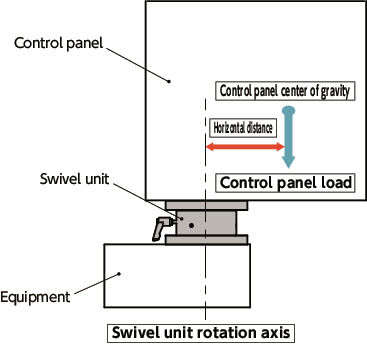

- When installing the control panel to be used, calculate the moment load it generates. Installation is possible if the moment load generated from the control panel does not exceed the allowable moment value.

Calculation Example of Moment Load Generated from Control Panel

<Conditions>Control panel load

= Control panel mass x gravity acceleration

= 30kg x 9.8

= 294N

Moment load generated from control panel

= Horizontal distance from swivel unit rotation axis to control panel center of gravity x control panel load

= 0.112m x 294N

= 32.9N・m

For example, the allowable moment for DKSF-115-45 is 200 N-m,

As 32.9N・m < 200N・m, control panel installation is possible

Durability Test Data

<DKSF-115-45 Test Conditions>Moment load generated from control panel : 200 N・m

Operation of 1 cycle : Rotate the control panel about 60° and return it to the original position

Number of test cycles : 21,000

<Operating Torque Change*1>

Before test : 5.1 N・m

After test : 13.0 N・m

<DKSF-130-60 Test Conditions>

Moment load generated from control panel : 315 N・m

Operation of 1 cycle : Rotate the control panel about 60° and return it to the original position

Number of test cycles : 21,000

<Operating Torque Change*1>

Before test : 4.2 N・m

After test : 25.9 N・m

*1: Operating torque is the value measured with the operating torque adjusting screw free.

Operating Torque Adjusting Method

Repeated use will lead to wear on the contact parts, reducing the operating torque. Adjust the operating torque periodically.

Mounting (Application: Post Type)

*2: Screws are not supplied.

Mounting (Application: Suspension Type)

*2: Screws are not supplied.