Hints for Correctly Using NBK Products

The video is an example using SSC (SSC). You can perform the same operation using this product.

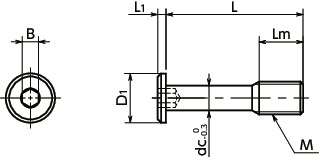

Unit : mm

| Part Number | M (Coarse) Nominal of Thread |

Pitch | L | Lm | D1 | L1 | B | dc | Max. Tightening Torque (N・m) |

Mass (g) |

CAD Download |

RFQ |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SSCHS-M8-25-SD | M8 | 1.25 | 25 | 10 | 11 | 1.5 | 4 | 6.3 | 5 | 7.9 | CAD | RFQ |

Nabeya Bi-tech Kaisha

Customer Service

Please enter questions about customization and other product-related inquiries here.

Find the inquiry form hereCharacteristics

- Prevents fallout and loss of the screw. They are intended to fix protective and inspection covers that are frequently installed and removed.

- All head heights are 1.5 mm or less. For space-saving of equipment/devices and applications with limited overhead space.

- For CE Marking compatibility.⇒Use the NBK Captive Screw Series to be comply with CE

Material/Finish

| SSCHS-HD | |

|---|---|

| Main Body | SUSXM7 (Equivalent to SUS304) |

| Strength Class | A2-40 |

Related Services

Application

For fixing protective covers and maintenance coversCE Marking compatible

Machine tools / Food machinery / Electrical and electronic equipment

Precautions for Use

- Screw hole inner diameter on the cover side shall be at least the dc dimension.

- The cover thickness should be 0.8 mm or above.

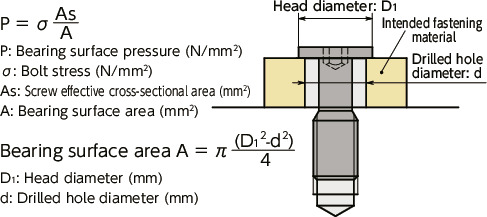

- Since the head bearing surface area is small, the bearing surface pressure increases.

- Using the following formula as a reference, ensure that the bearing surface pressure due to screw tightening does not exceed the permitted surface pressure of the intended fastening material.

Head Diameter and Screw Effective Cross-Sectional Area

| Part Number | Head Diameter (mm) | Screw Effective Cross-Sectional Area (mm2) |

|---|---|---|

| SSCHS-M3-SD | 5 | 5.03 |

| SSCHS-M4-SD | 6 | 8.78 |

| SSCHS-M5-SD | 8 | 14.2 |

| SSCHS-M6-SD | 9 | 20.1 |

| SSCHS-M8-SD | 11 | 36.6 |

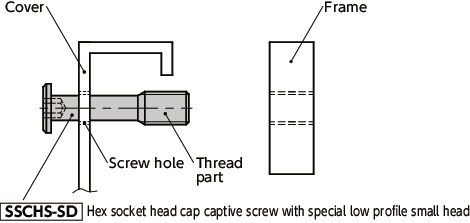

Installation Example

Make a screw hole in the cover, and then pass the SSCHS-SD thread part through it. Even when the screw is removed from the frame, SSCHS-SD does not fall out of the cover because the SSCHS-SD thread part catches on the cover screw hole.