Specs/CAD

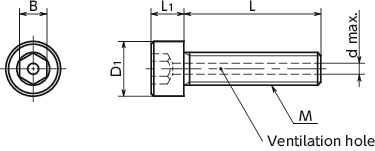

Unit : mm

| Part Number | M (Coarse) Nominal of Thread |

Pitch | L | D1 | L1 | B | d Max. |

Mass (g) |

CAD Download |

RFQ |

|---|---|---|---|---|---|---|---|---|---|---|

| SVSLG-M3-6-PN | M3 | 0.5 | 6 | 5.5 | 3 | 2.5 | 1.2 | 0.64 | CAD | RFQ |

| SVSLG-M3-8-PN | M3 | 0.5 | 8 | 5.5 | 3 | 2.5 | 1.2 | 0.81 | CAD | RFQ |

| SVSLG-M3-10-PN | M3 | 0.5 | 10 | 5.5 | 3 | 2.5 | 1.2 | 0.86 | CAD | RFQ |

| SVSLG-M3-12-PN | M3 | 0.5 | 12 | 5.5 | 3 | 2.5 | 1.2 | 0.9 | CAD | RFQ |

| SVSLG-M3-15-PN | M3 | 0.5 | 15 | 5.5 | 3 | 2.5 | 1.2 | 0.9 | CAD | RFQ |

| SVSLG-M3-20-PN | M3 | 0.5 | 20 | 5.5 | 3 | 2.5 | 1.2 | 1.28 | CAD | RFQ |

| SVSLG-M3-25-PN | M3 | 0.5 | 25 | 5.5 | 3 | 2.5 | 1.2 | 1.45 | CAD | RFQ |

| SVSLG-M4-8-PN | M4 | 0.7 | 8 | 7 | 4 | 3 | 1.5 | 1.4 | CAD | RFQ |

| SVSLG-M4-10-PN | M4 | 0.7 | 10 | 7 | 4 | 3 | 1.5 | 1.6 | CAD | RFQ |

| SVSLG-M4-12-PN | M4 | 0.7 | 12 | 7 | 4 | 3 | 1.5 | 1.8 | CAD | RFQ |

| SVSLG-M4-15-PN | M4 | 0.7 | 15 | 7 | 4 | 3 | 1.5 | 2 | CAD | RFQ |

| SVSLG-M4-20-PN | M4 | 0.7 | 20 | 7 | 4 | 3 | 1.5 | 2.3 | CAD | RFQ |

| SVSLG-M4-25-PN | M4 | 0.7 | 25 | 7 | 4 | 3 | 1.5 | 2.7 | CAD | RFQ |

| SVSLG-M5-10-PN | M5 | 0.8 | 10 | 8.5 | 5 | 4 | 1.5 | 2.5 | CAD | RFQ |

| SVSLG-M5-12-PN | M5 | 0.8 | 12 | 8.5 | 5 | 4 | 1.5 | 2.8 | CAD | RFQ |

| SVSLG-M5-15-PN | M5 | 0.8 | 15 | 8.5 | 5 | 4 | 1.5 | 3.3 | CAD | RFQ |

| SVSLG-M5-20-PN | M5 | 0.8 | 20 | 8.5 | 5 | 4 | 1.5 | 3.7 | CAD | RFQ |

| SVSLG-M5-25-PN | M5 | 0.8 | 25 | 8.5 | 5 | 4 | 1.5 | 4.4 | CAD | RFQ |

| SVSLG-M5-30-PN | M5 | 0.8 | 30 | 8.5 | 5 | 4 | 1.5 | 5.1 | CAD | RFQ |

| SVSLG-M6-12-PN | M6 | 1 | 12 | 10 | 6 | 5 | 2 | 4.7 | CAD | RFQ |

| SVSLG-M6-15-PN | M6 | 1 | 15 | 10 | 6 | 5 | 2 | 5.2 | CAD | RFQ |

| SVSLG-M6-20-PN | M6 | 1 | 20 | 10 | 6 | 5 | 2 | 5.8 | CAD | RFQ |

| SVSLG-M6-25-PN | M6 | 1 | 25 | 10 | 6 | 5 | 2 | 6.7 | CAD | RFQ |

| SVSLG-M6-30-PN | M6 | 1 | 30 | 10 | 6 | 5 | 2 | 7.3 | CAD | RFQ |

● Batch cleanroom packing is provided for orders containing multiple items of the same size.

Nabeya Bi-tech Kaisha

Customer Service

Please enter questions about customization and other product-related inquiries here.

Find the inquiry form hereRelated Services

Material/Finish

| SVSLG-PN | |

|---|---|

| Main Body | SUS316L Surface Hardening Treatment |

Application

Vacuum devices / Vacuum chambers / FPD production equipment / Semiconductor manufacturing equipment / Electron microscopes / Food machineryCharacteristics

- High strength stainless steel hex socket head cap screws.

- The proof load is approximately 1.8 times that of general stainless steel hex socket head cap screws. Therefore, smaller screw diameters and reduced quantities are available to save space and reduce weight.

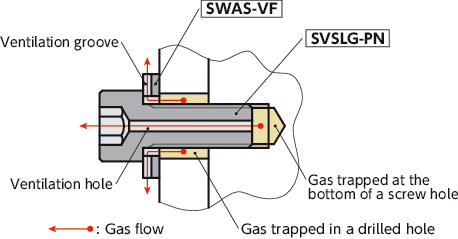

- The ventilation hole easily releases gas trapped in the screw holes of equipment and machines, and supports vacuum drawing of vacuum devices.

- Galling and seizing are prevented by curing the screw surface.

- Unlike plating or coating, there is nothing adhering to the surface, eliminating concerns about contamination due to stripping when tightening.

- Suitable for preventing seizing in environments where lubricant cannot be used.

- For the characteristics of special surface hardening treatment, see “Advantages of Special Surface Hardened Screws”.

- Cleanroom washing/cleanroom packing provided.⇒Cleanroom Wash / Cleanroom Packing Service

Usage Example

Gas trapped at the bottom of the screw hole is released through SVSLG-PN, and gas trapped in the drilled hole is released through SWAS-VF.SWAS-VFSWAS-VF-PC

Precautions for Use

May have lower corrosion resistance than general SUS316L.We recommend performing a test under the same usage conditions as in actual usage in advance.

Mechanical Properties

| Part Number / Strength Class | Property | ||

|---|---|---|---|

| Tensile Strength (N/mm2) | 0.2% Proof Load (N/mm2) | Elongation (mm) | |

| SVSLG-PN *1 | 1000 | 800 | 0.3d |

| A2-70/A4-70*2 | 700 | 450 | 0.4d |

| A2-50/A4-50*2 | 500 | 210 | 0.6d |

*1: In-house specification value. Confirmed with test pieces (pre-treatment materials) from each production lot.

*2: Specification value from JIS B 1054-1:2013 (ISO 3506-1:2009) "Mechanical properties of corrosion-resistant stainless steel fasteners-Part 1: Bolts, screws and studs". Values in chart are for reference only. They are not guaranteed values.