Specs/CAD

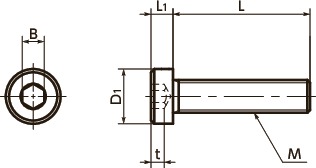

Unit : mm

| Part Number | M (Coarse) Nominal of Thread |

Pitch | L | D1 | B | t | L1 | Max. Torque (N・m) |

Qty per Pack | Mass (g) |

CAD Download |

RFQ |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SLHL-M3-6 | M3 | 0.5 | 6 | 5.5 | 2 | 1.5 | 2 | 1.2 | 20 | 0.53 | CAD | RFQ |

| SLHL-M3-8 | M3 | 0.5 | 8 | 5.5 | 2 | 1.5 | 2 | 1.2 | 20 | 0.62 | CAD | RFQ |

| SLHL-M3-10 | M3 | 0.5 | 10 | 5.5 | 2 | 1.5 | 2 | 1.2 | 20 | 0.7 | CAD | RFQ |

| SLHL-M4-6 | M4 | 0.7 | 6 | 7 | 2.5 | 2.3 | 2.8 | 3.2 | 20 | 1.1 | CAD | RFQ |

| SLHL-M4-8 | M4 | 0.7 | 8 | 7 | 2.5 | 2.3 | 2.8 | 3.2 | 20 | 1.3 | CAD | RFQ |

| SLHL-M4-10 | M4 | 0.7 | 10 | 7 | 2.5 | 2.3 | 2.8 | 3.2 | 20 | 1.4 | CAD | RFQ |

| SLHL-M4-12 | M4 | 0.7 | 12 | 7 | 2.5 | 2.3 | 2.8 | 3.2 | 20 | 1.6 | CAD | RFQ |

| SLHL-M5-8 | M5 | 0.8 | 8 | 8.5 | 3 | 2.7 | 3.5 | 6.4 | 10 | 1.8 | CAD | RFQ |

| SLHL-M5-10 | M5 | 0.8 | 10 | 8.5 | 3 | 2.7 | 3.5 | 6.4 | 10 | 2 | CAD | RFQ |

| SLHL-M5-12 | M5 | 0.8 | 12 | 8.5 | 3 | 2.7 | 3.5 | 6.4 | 10 | 2.3 | CAD | RFQ |

| SLHL-M5-16 | M5 | 0.8 | 16 | 8.5 | 3 | 2.7 | 3.5 | 6.4 | 10 | 2.8 | CAD | RFQ |

| SLHL-M6-10 | M6 | 1 | 10 | 10 | 4 | 3 | 4 | 11 | 10 | 3.5 | CAD | RFQ |

| SLHL-M6-12 | M6 | 1 | 12 | 10 | 4 | 3 | 4 | 11 | 10 | 3.8 | CAD | RFQ |

| SLHL-M6-16 | M6 | 1 | 16 | 10 | 4 | 3 | 4 | 11 | 10 | 4.5 | CAD | RFQ |

| SLHL-M6-20 | M6 | 1 | 20 | 10 | 4 | 3 | 4 | 11 | 10 | 5.3 | CAD | RFQ |

Nabeya Bi-tech Kaisha

Customer Service

Please enter questions about customization and other product-related inquiries here.

Find the inquiry form here

● When purchasing less volume than one full bag, a separate handling fee is charged. For details, see the Sold Separately Service.

Related Services

Material/Finish

| SLHL | |

|---|---|

| Main Body | SUS316L |

| Strength Class | A4-70 |

Do not exceed the max. tightening torque.

Application

Reducing the size of equipment and devicesFPD production equipment/Semiconductor devices/

Aquatic applications/General industrial machines

Characteristics

- Socket head cap screws with low profile made of SUS316L.

- Intended for reducing the size of devices and applications with limited overhead space.

- Compared to SUS304, SUS316L has excellent hydrogen embrittlement resistance, fluorine and chlorine gas resistance, and heat resistance. This screw also has corrosion resistance against chemical products and seawater environments that matches or exceeds SUS304.

- SUS316L is non-magnetic.

- Conforms to DIN 7984.

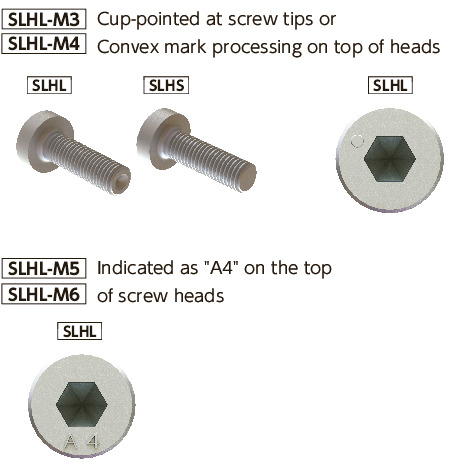

- To distinguish fromSLHS, following processing are made.