Hints for Correctly Using NBK Products

The video is an example using SSC (SSC). You can perform the same operation using this product.

Specs/CAD

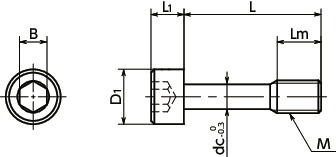

Unit : mm

| Part Number | M (Coarse) Nominal of Thread |

Pitch | L | Lm | D1 | L1 | B | dc | Mass (g) |

CAD Download |

RFQ |

|---|---|---|---|---|---|---|---|---|---|---|---|

| SSC-SNSLG-M4-10 | M4 | 0.7 | 10 | 5 | 7 | 4 | 3 | 3 | 1.8 | CAD | RFQ |

| SSC-SNSLG-M4-12 | M4 | 0.7 | 12 | 5 | 7 | 4 | 3 | 3 | 2 | CAD | RFQ |

| SSC-SNSLG-M4-15 | M4 | 0.7 | 15 | 5 | 7 | 4 | 3 | 3 | 2.3 | CAD | RFQ |

| SSC-SNSLG-M4-20 | M4 | 0.7 | 20 | 5 | 7 | 4 | 3 | 3 | 2.7 | CAD | RFQ |

Nabeya Bi-tech Kaisha

Customer Service

Please enter questions about customization and other product-related inquiries here.

Find the inquiry form hereRelated Services

Material/Finish

| SSC-SNSLG | |

|---|---|

| Main Body | SUS316L |

Application

For fixing protective covers and maintenance coversCE Marking compatible

Machine tools / Food machinery / Electrical and electronic equipment

Characteristics

- Prevents fall-off and loss of the screw. They are intended to fix protective and inspection covers that are frequently installed and removed.

- For CE Marking compatibility. ⇒Use the NBK Captive Screw Series to be comply with CE

- High intensity stainless steel hex socket head cap screw.

- Main body tensile strength is 1000 N/mm2, 0.2% proof load 800 N/mm2.

- The proof load is approximately 1.8 times that of general stainless steel hex socket head cap screws. Therefore, smaller screw diameters and reduced quantities are available to save space and reduce weight.

- Made of SUS316L. It has excellent corrosion resistance.

- Non-magnetic.

Precautions for Use

- Screw hole inner diameter on the cover side shall be at least the dc dimension.

- The cover thickness should be 0.8mm or above.

Mechanical Properties

| Part Number / Strength Class | Property | ||

|---|---|---|---|

| Tensile Strength (N/mm2) | 0.2% Proof Load (N/mm2) | Elongation (mm) | |

| SSC-SNSLG *1 | 1000 | 800 | 0.3d |

| A2-70/A4-70*2 | 700 | 450 | 0.4d |

| A2-50/A4-50*2 | 500 | 210 | 0.6d |

*1: In-house specification value. Confirmed with test pieces from each production lot.

*2: Specification value from JIS B 1054-1:2013 (ISO 3506-1:2009) "Mechanical properties of corrosion-resistant stainless steel fasteners-Part 1: Bolts, screws and studs".

Values in chart are for reference only. They are not guaranteed values.

Magnetic permeability comparison

| Part Number / Material | Magnetic Permeability |

|---|---|

| SSC-SNSLG SUS316L | 1.008 |

| SNSL SUS316L | 1.006 |

| SUSXM7 | 1.4 |

Values in chart are for reference only. They are not guaranteed values.

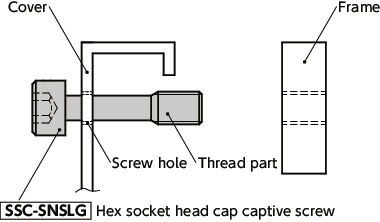

Installation Example

Make a screw hole in the cover, and then pass the SSC-SNSLG thread part through it. Even when the screw is removed from the frame, SSC-SNSLG does not fall out of the cover because the SSC-SNSLG thread part catches on the cover screw hole.