Hints for Correctly Using NBK Products

The video is an example using SSC (SSC). You can perform the same operation using this product.

Specs/CAD

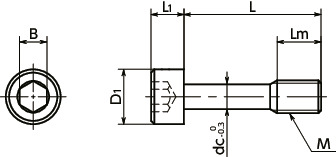

Unit : mm

| Part Number | M (Coarse) Nominal of Thread |

Pitch | L | Lm | D1 | L1 | B | dc | Mass (g) |

CAD Download |

RFQ |

|---|---|---|---|---|---|---|---|---|---|---|---|

| SSC-SNSTG-M6-12 | M6 | 1 | 12 | 8 | 10 | 6 | 5 | 4.5 | 2.6 | CAD | RFQ |

| SSC-SNSTG-M6-16 | M6 | 1 | 16 | 8 | 10 | 6 | 5 | 4.5 | 2.7 | CAD | RFQ |

| SSC-SNSTG-M6-20 | M6 | 1 | 20 | 8 | 10 | 6 | 5 | 4.5 | 2.8 | CAD | RFQ |

| SSC-SNSTG-M6-25 | M6 | 1 | 25 | 8 | 10 | 6 | 5 | 4.5 | 2.9 | CAD | RFQ |

| SSC-SNSTG-M6-30 | M6 | 1 | 30 | 8 | 10 | 6 | 5 | 4.5 | 3 | CAD | RFQ |

● Batch cleanroom packing is provided for orders containing multiple items of the same size.

Nabeya Bi-tech Kaisha

Customer Service

Please enter questions about customization and other product-related inquiries here.

Find the inquiry form hereMaterial/Finish

| SSC-SNSTG | |

|---|---|

| Main Body | Ti-6Al-4V (64 Titanium) |

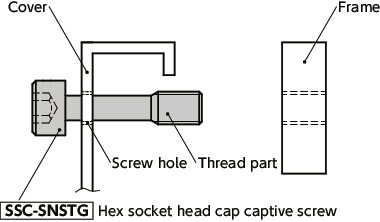

Application

For fixing protective covers and maintenance coversCE Marking compatible

Machine tools / Food machinery / Electrical and electronic equipment

Characteristics

- Prevents fall-off and loss of the screw. They are intended to fix protective and inspection covers that are frequently installed and removed.

- For CE Marking compatibility. ⇒Use the NBK Captive Screw Series to be comply with CE

- Made of high-strength titanium alloy.

- The specific gravity is approximately 60% that of stainless steel.

- Non-magnetic.

- Resistant to corrosion and with especially good seawater resistance.

- For the properties of titanium materials, see "Properties of Titanium." ⇒Properties of Titanium

- Cleanroom wash/cleanroom packing provided.⇒Cleanroom Wash / Cleanroom Packing Service

Precautions for Use

- Screw hole inner diameter on the cover side shall be at least the dc dimension.

- The cover thickness should be 0.8mm or above.

Mechanical Properties

| Ti-6Al-4V (64 Titanium) | |

|---|---|

| Tensile Strength (N/mm2) | 895 or Higher |

| 0.2% Proof Load (N/mm2) | 825 or Higher |

| Elongation (%) | 10 or Higher |

Values in chart are for reference only. They are not guaranteed values.

Physical Properties

| Ti-6Al-4V (64 Titanium) | |

|---|---|

| Specific Gravity | 4.43 |

| Melting Point (°C) | 1540 |

| Longitudinal Elastic Modulus (GPa) | 113 |

| Thermal Conductivity (W/(m・K)) | 7.5 |

| Linear Expansion Coefficient (K-1) | 8.8 × 10-6 |

| Electric Resistance (µΩ・m) | 1.7 |

| Magnetic Permeability (µ) | 1.0002 (Nonmagnetic) |

Values in chart are for reference only. They are not guaranteed values.

Installation Example

Make a screw hole in the cover, and then pass the SSC-SNSTG thread part through it. Even when the screw is removed from the frame, SSC-SNSTG does not fall out of the cover because the SSC-SNSTG thread part catches on the cover screw hole.