Specs/CAD

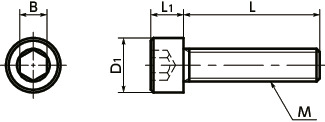

Unit : mm

| Part Number | M (Coarse) Nominal of Thread |

Pitch | L | D1 | L1 | B | Tensile Breaking Load (N)*1 |

Torsional Torque (N・m)*1 |

Qty per Pack | Mass (g) |

CAD Download |

RFQ |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SPC-M3-6-C | M3 | 0.5 | 6 | 5.5 | 3 | 2.5 | 266 | 0.18 | 20 | 0.11 | CAD | RFQ |

| SPC-M3-8-C | M3 | 0.5 | 8 | 5.5 | 3 | 2.5 | 266 | 0.18 | 20 | 0.12 | CAD | RFQ |

| SPC-M3-10-C | M3 | 0.5 | 10 | 5.5 | 3 | 2.5 | 266 | 0.18 | 20 | 0.14 | CAD | RFQ |

| SPC-M3-12-C | M3 | 0.5 | 12 | 5.5 | 3 | 2.5 | 266 | 0.18 | 20 | 0.15 | CAD | RFQ |

| SPC-M3-15-C | M3 | 0.5 | 15 | 5.5 | 3 | 2.5 | 266 | 0.18 | 20 | 0.17 | CAD | RFQ |

| SPC-M3-20-C | M3 | 0.5 | 20 | 5.5 | 3 | 2.5 | 266 | 0.18 | 20 | 0.21 | CAD | RFQ |

| SPC-M3-25-C | M3 | 0.5 | 25 | 5.5 | 3 | 2.5 | 266 | 0.18 | 20 | 0.25 | CAD | RFQ |

| SPC-M3-6-C(1000) | M3 | 0.5 | 6 | 5.5 | 3 | 2.5 | 266 | 0.18 | 1000 | 0.11 | CAD | RFQ |

| SPC-M3-8-C(1000) | M3 | 0.5 | 8 | 5.5 | 3 | 2.5 | 266 | 0.18 | 1000 | 0.12 | CAD | RFQ |

| SPC-M3-10-C(1000) | M3 | 0.5 | 10 | 5.5 | 3 | 2.5 | 266 | 0.18 | 1000 | 0.14 | CAD | RFQ |

| SPC-M3-12-C(1000) | M3 | 0.5 | 12 | 5.5 | 3 | 2.5 | 266 | 0.18 | 1000 | 0.15 | CAD | RFQ |

| SPC-M3-15-C(1000) | M3 | 0.5 | 15 | 5.5 | 3 | 2.5 | 266 | 0.18 | 1000 | 0.17 | CAD | RFQ |

| SPC-M3-20-C(1000) | M3 | 0.5 | 20 | 5.5 | 3 | 2.5 | 266 | 0.18 | 1000 | 0.21 | CAD | RFQ |

| SPC-M3-25-C(1000) | M3 | 0.5 | 25 | 5.5 | 3 | 2.5 | 266 | 0.18 | 1000 | 0.25 | CAD | RFQ |

| SPC-M4-6-C | M4 | 0.7 | 6 | 7 | 4 | 3 | 481 | 0.39 | 20 | 0.23 | CAD | RFQ |

| SPC-M4-8-C | M4 | 0.7 | 8 | 7 | 4 | 3 | 481 | 0.39 | 20 | 0.25 | CAD | RFQ |

| SPC-M4-10-C | M4 | 0.7 | 10 | 7 | 4 | 3 | 481 | 0.39 | 20 | 0.28 | CAD | RFQ |

| SPC-M4-12-C | M4 | 0.7 | 12 | 7 | 4 | 3 | 481 | 0.39 | 20 | 0.3 | CAD | RFQ |

| SPC-M4-15-C | M4 | 0.7 | 15 | 7 | 4 | 3 | 481 | 0.39 | 20 | 0.34 | CAD | RFQ |

| SPC-M4-20-C | M4 | 0.7 | 20 | 7 | 4 | 3 | 481 | 0.39 | 20 | 0.41 | CAD | RFQ |

| SPC-M4-25-C | M4 | 0.7 | 25 | 7 | 4 | 3 | 481 | 0.39 | 20 | 0.48 | CAD | RFQ |

| SPC-M4-6-C(1000) | M4 | 0.7 | 6 | 7 | 4 | 3 | 481 | 0.39 | 1000 | 0.23 | CAD | RFQ |

| SPC-M4-8-C(1000) | M4 | 0.7 | 8 | 7 | 4 | 3 | 481 | 0.39 | 1000 | 0.25 | CAD | RFQ |

| SPC-M4-10-C(1000) | M4 | 0.7 | 10 | 7 | 4 | 3 | 481 | 0.39 | 1000 | 0.28 | CAD | RFQ |

| SPC-M4-12-C(1000) | M4 | 0.7 | 12 | 7 | 4 | 3 | 481 | 0.39 | 1000 | 0.3 | CAD | RFQ |

| SPC-M4-15-C(1000) | M4 | 0.7 | 15 | 7 | 4 | 3 | 481 | 0.39 | 1000 | 0.34 | CAD | RFQ |

| SPC-M4-20-C(500) | M4 | 0.7 | 20 | 7 | 4 | 3 | 481 | 0.39 | 500 | 0.41 | CAD | RFQ |

| SPC-M4-25-C(500) | M4 | 0.7 | 25 | 7 | 4 | 3 | 481 | 0.39 | 500 | 0.48 | CAD | RFQ |

| SPC-M5-10-C | M5 | 0.8 | 10 | 8.5 | 5 | 4 | 797 | 0.8 | 20 | 0.42 | CAD | RFQ |

| SPC-M5-12-C | M5 | 0.8 | 12 | 8.5 | 5 | 4 | 797 | 0.8 | 20 | 0.45 | CAD | RFQ |

| SPC-M5-15-C | M5 | 0.8 | 15 | 8.5 | 5 | 4 | 797 | 0.8 | 20 | 0.52 | CAD | RFQ |

| SPC-M5-20-C | M5 | 0.8 | 20 | 8.5 | 5 | 4 | 797 | 0.8 | 20 | 0.62 | CAD | RFQ |

| SPC-M5-25-C | M5 | 0.8 | 25 | 8.5 | 5 | 4 | 797 | 0.8 | 20 | 0.74 | CAD | RFQ |

| SPC-M5-30-C | M5 | 0.8 | 30 | 8.5 | 5 | 4 | 797 | 0.8 | 20 | 0.85 | CAD | RFQ |

| SPC-M5-35-C | M5 | 0.8 | 35 | 8.5 | 5 | 4 | 797 | 0.8 | 20 | 0.97 | CAD | RFQ |

| SPC-M5-10-C(500) | M5 | 0.8 | 10 | 8.5 | 5 | 4 | 797 | 0.8 | 500 | 0.42 | CAD | RFQ |

| SPC-M5-12-C(500) | M5 | 0.8 | 12 | 8.5 | 5 | 4 | 797 | 0.8 | 500 | 0.45 | CAD | RFQ |

| SPC-M5-15-C(500) | M5 | 0.8 | 15 | 8.5 | 5 | 4 | 797 | 0.8 | 500 | 0.52 | CAD | RFQ |

| SPC-M5-20-C(500) | M5 | 0.8 | 20 | 8.5 | 5 | 4 | 797 | 0.8 | 500 | 0.62 | CAD | RFQ |

| SPC-M5-25-C(250) | M5 | 0.8 | 25 | 8.5 | 5 | 4 | 797 | 0.8 | 250 | 0.74 | CAD | RFQ |

| SPC-M5-30-C(250) | M5 | 0.8 | 30 | 8.5 | 5 | 4 | 797 | 0.8 | 250 | 0.85 | CAD | RFQ |

| SPC-M5-35-C(250) | M5 | 0.8 | 35 | 8.5 | 5 | 4 | 797 | 0.8 | 250 | 0.97 | CAD | RFQ |

| SPC-M6-10-C | M6 | 1 | 10 | 10 | 6 | 5 | 1136 | 1.2 | 20 | 0.72 | CAD | RFQ |

| SPC-M6-15-C | M6 | 1 | 15 | 10 | 6 | 5 | 1136 | 1.2 | 20 | 0.78 | CAD | RFQ |

| SPC-M6-20-C | M6 | 1 | 20 | 10 | 6 | 5 | 1136 | 1.2 | 20 | 0.85 | CAD | RFQ |

| SPC-M6-25-C | M6 | 1 | 25 | 10 | 6 | 5 | 1136 | 1.2 | 20 | 1.2 | CAD | RFQ |

| SPC-M6-30-C | M6 | 1 | 30 | 10 | 6 | 5 | 1136 | 1.2 | 20 | 1.3 | CAD | RFQ |

| SPC-M6-35-C | M6 | 1 | 35 | 10 | 6 | 5 | 1136 | 1.2 | 20 | 1.6 | CAD | RFQ |

| SPC-M6-40-C | M6 | 1 | 40 | 10 | 6 | 5 | 1136 | 1.2 | 20 | 1.7 | CAD | RFQ |

| SPC-M6-10-C(500) | M6 | 1 | 10 | 10 | 6 | 5 | 1136 | 1.2 | 500 | 0.72 | CAD | RFQ |

| SPC-M6-15-C(500) | M6 | 1 | 15 | 10 | 6 | 5 | 1136 | 1.2 | 500 | 0.78 | CAD | RFQ |

| SPC-M6-20-C(250) | M6 | 1 | 20 | 10 | 6 | 5 | 1136 | 1.2 | 250 | 0.85 | CAD | RFQ |

| SPC-M6-25-C(250) | M6 | 1 | 25 | 10 | 6 | 5 | 1136 | 1.2 | 250 | 1.2 | CAD | RFQ |

| SPC-M6-30-C(200) | M6 | 1 | 30 | 10 | 6 | 5 | 1136 | 1.2 | 200 | 1.3 | CAD | RFQ |

| SPC-M6-35-C(200) | M6 | 1 | 35 | 10 | 6 | 5 | 1136 | 1.2 | 200 | 1.6 | CAD | RFQ |

| SPC-M6-40-C(100) | M6 | 1 | 40 | 10 | 6 | 5 | 1136 | 1.2 | 100 | 1.7 | CAD | RFQ |

| SPC-M8-10-C | M8 | 1.25 | 10 | 13 | 8 | 6 | 2088 | 3.2 | 20 | 1.6 | CAD | RFQ |

| SPC-M8-15-C | M8 | 1.25 | 15 | 13 | 8 | 6 | 2088 | 3.2 | 20 | 1.9 | CAD | RFQ |

| SPC-M8-20-C | M8 | 1.25 | 20 | 13 | 8 | 6 | 2088 | 3.2 | 20 | 2.1 | CAD | RFQ |

| SPC-M8-25-C | M8 | 1.25 | 25 | 13 | 8 | 6 | 2088 | 3.2 | 20 | 2.4 | CAD | RFQ |

| SPC-M8-30-C | M8 | 1.25 | 30 | 13 | 8 | 6 | 2088 | 3.2 | 20 | 2.6 | CAD | RFQ |

| SPC-M8-35-C | M8 | 1.25 | 35 | 13 | 8 | 6 | 2088 | 3.2 | 20 | 3 | CAD | RFQ |

| SPC-M8-40-C | M8 | 1.25 | 40 | 13 | 8 | 6 | 2088 | 3.2 | 20 | 3.3 | CAD | RFQ |

| SPC-M8-10-C(250) | M8 | 1.25 | 10 | 13 | 8 | 6 | 2088 | 3.2 | 250 | 1.6 | CAD | RFQ |

| SPC-M8-15-C(200) | M8 | 1.25 | 15 | 13 | 8 | 6 | 2088 | 3.2 | 200 | 1.9 | CAD | RFQ |

| SPC-M8-20-C(200) | M8 | 1.25 | 20 | 13 | 8 | 6 | 2088 | 3.2 | 200 | 2.1 | CAD | RFQ |

| SPC-M8-25-C(100) | M8 | 1.25 | 25 | 13 | 8 | 6 | 2088 | 3.2 | 100 | 2.4 | CAD | RFQ |

| SPC-M8-30-C(100) | M8 | 1.25 | 30 | 13 | 8 | 6 | 2088 | 3.2 | 100 | 2.6 | CAD | RFQ |

| SPC-M8-35-C(100) | M8 | 1.25 | 35 | 13 | 8 | 6 | 2088 | 3.2 | 100 | 3 | CAD | RFQ |

| SPC-M8-40-C(100) | M8 | 1.25 | 40 | 13 | 8 | 6 | 2088 | 3.2 | 100 | 3.3 | CAD | RFQ |

*1: Values in chart are for reference only. They are not guaranteed values. The recommended tightening torque is 50% of the torsional torque.

Nabeya Bi-tech Kaisha

Customer Service

Please enter questions about customization and other product-related inquiries here.

Find the inquiry form hereRelated Services

Material/Finish

| SPC-C | |

|---|---|

| Main Body | PC (Polycarbonate) (Transparent) |

| Heat Resistance Temperature*1 | 115℃ |

*1: This is the value for the resin material. The operating temperature of the product changes with performance conditions such as tightening torque.

Application

Electrical and electronic equipmentCharacteristics

- PC (polycarbonate) hex socket head cap screws.

- PC (polycarbonate) has the highest shock resistance of engineering plastics.

- Allowable operating temperature*1 (min./max.): -40°C/115°C

- PC has low water absorbency and excellent weather resistance.

- For the properties and precautions for use of plastic screws, see “Properties of Plastic Screws.”⇒Plastic Screws

/14306_1.jpg?upd=20251201134223&awscf_publishdate=2026-02-04 16:40)