Hints for Correctly Using NBK Products

The video is an example using SSC (SSC). You can perform the same operation using this product.

Specs/CAD

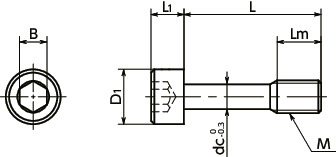

Unit : mm

| Part Number | M (Coarse) Nominal of Thread |

Pitch | L | Lm | D1 | L1 | B | dc | Mass (g) |

CAD Download |

RFQ |

|---|---|---|---|---|---|---|---|---|---|---|---|

| SSC-M6-12-TF | M6 | 1 | 12 | 8 | 10 | 6 | 5 | 4.5 | 5.1 | CAD | RFQ |

| SSC-M6-16-TF | M6 | 1 | 16 | 8 | 10 | 6 | 5 | 4.5 | 5.8 | CAD | RFQ |

| SSC-M6-20-TF | M6 | 1 | 20 | 8 | 10 | 6 | 5 | 4.5 | 6.5 | CAD | RFQ |

| SSC-M6-25-TF | M6 | 1 | 25 | 8 | 10 | 6 | 5 | 4.5 | 7.6 | CAD | RFQ |

| SSC-M6-30-TF | M6 | 1 | 30 | 8 | 10 | 6 | 5 | 4.5 | 8.3 | CAD | RFQ |

Nabeya Bi-tech Kaisha

Customer Service

Please enter questions about customization and other product-related inquiries here.

Find the inquiry form hereRelated Services

Material/Finish

| SSC-TF | |

|---|---|

| Main Body | SUSXM7 (Equivalent to SUS304) PTFE (Tetrafluoroethylene) Coating |

| Strength Class | A2 - 70 |

Application

For fixing protective covers and maintenance coversCE Marking compatible

Machine tools / Food machinery / Electrical and electronic equipment

Characteristics

- Prevents fall-off and loss of the screw. They are intended to fix protective and inspection covers that are frequently installed and removed.

- For CE Marking compatibility. ⇒Use the NBK Captive Screw Series to be comply with CE

- Excellent chemical resistance.

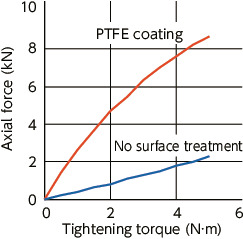

- Excellent lubrication property. Suitable for preventing seizing.

Precautions for Use

- Screw hole inner diameter on the cover side shall be at least the dc dimension.

- The cover thickness should be 0.8mm or above.

Tightening Property (Reference)

Reference data for Hex Socket Head Cap Screw - PTFE Coating SNSS-M5-25-TF.⇒The Features of Screws with Special Surface Treatment

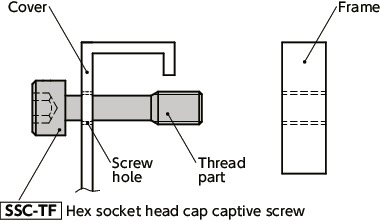

Installation Example

Make a screw hole in the cover, and then pass the SSC-TF thread part through it. Even when the screw is removed from the frame, SSC-TF does not fall out of the cover because the SSC-TF thread part catches on the cover screw hole.