Specs/CAD

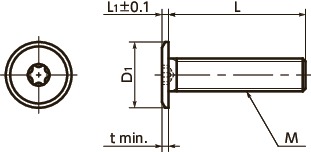

Unit : mm

| Part Number | M (Coarse) Nominal of Thread |

Pitch | L | D1 | L1 | Key Part No. | Hexalobular Socket No. | t | Max. Torque(N・m) | Qty per Pack | Mass (g) |

CAD Download |

RFQ |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SETS-M2-4 | M2 | 0.4 | 4 | 4-0.4~0 | 0.5 | SKX-4 | 4 | 0.4 | 0.15 | 20 | 0.047 | CAD | RFQ |

| SETS-M2-5 | M2 | 0.4 | 5 | 4-0.4~0 | 0.5 | SKX-4 | 4 | 0.4 | 0.15 | 20 | 0.067 | CAD | RFQ |

| SETS-M2-6 | M2 | 0.4 | 6 | 4-0.4~0 | 0.5 | SKX-4 | 4 | 0.4 | 0.15 | 20 | 0.087 | CAD | RFQ |

| SETS-M2-8 | M2 | 0.4 | 8 | 4-0.4~0 | 0.5 | SKX-4 | 4 | 0.4 | 0.15 | 20 | 0.13 | CAD | RFQ |

| SETS-M2-10 | M2 | 0.4 | 10 | 4-0.4~0 | 0.5 | SKX-4 | 4 | 0.4 | 0.15 | 20 | 0.17 | CAD | RFQ |

| SETS-M2-12 | M2 | 0.4 | 12 | 4-0.4~0 | 0.5 | SKX-4 | 4 | 0.4 | 0.15 | 20 | 0.23 | CAD | RFQ |

| SETS-M2.6-4 | M2.6 | 0.45 | 4 | 6-0.5~0 | 0.6 | SKX-5 | 5 | 0.5 | 0.3 | 20 | 0.17 | CAD | RFQ |

| SETS-M2.6-5 | M2.6 | 0.45 | 5 | 6-0.5~0 | 0.6 | SKX-5 | 5 | 0.5 | 0.3 | 20 | 0.2 | CAD | RFQ |

| SETS-M2.6-6 | M2.6 | 0.45 | 6 | 6-0.5~0 | 0.6 | SKX-5 | 5 | 0.5 | 0.3 | 20 | 0.23 | CAD | RFQ |

| SETS-M2.6-8 | M2.6 | 0.45 | 8 | 6-0.5~0 | 0.6 | SKX-5 | 5 | 0.5 | 0.3 | 20 | 0.29 | CAD | RFQ |

| SETS-M2.6-10 | M2.6 | 0.45 | 10 | 6-0.5~0 | 0.6 | SKX-5 | 5 | 0.5 | 0.3 | 20 | 0.35 | CAD | RFQ |

| SETS-M2.6-12 | M2.6 | 0.45 | 12 | 6-0.5~0 | 0.6 | SKX-5 | 5 | 0.5 | 0.3 | 20 | 0.41 | CAD | RFQ |

| SETS-M3-6 | M3 | 0.5 | 6 | 7-0.5~0 | 0.8 | SKX-6 | 6 | 0.75 | 0.6 | 20 | 0.39 | CAD | RFQ |

| SETS-M3-8 | M3 | 0.5 | 8 | 7-0.5~0 | 0.8 | SKX-6 | 6 | 0.75 | 0.6 | 20 | 0.48 | CAD | RFQ |

| SETS-M3-10 | M3 | 0.5 | 10 | 7-0.5~0 | 0.8 | SKX-6 | 6 | 0.75 | 0.6 | 20 | 0.56 | CAD | RFQ |

| SETS-M3-12 | M3 | 0.5 | 12 | 7-0.5~0 | 0.8 | SKX-6 | 6 | 0.75 | 0.6 | 20 | 0.64 | CAD | RFQ |

| SETS-M3-16 | M3 | 0.5 | 16 | 7-0.5~0 | 0.8 | SKX-6 | 6 | 0.75 | 0.6 | 20 | 0.84 | CAD | RFQ |

| SETS-M4-6 | M4 | 0.7 | 6 | 8-0.5~0 | 0.9 | SKX-8 | 8 | 0.9 | 1.5 | 20 | 0.65 | CAD | RFQ |

| SETS-M4-8 | M4 | 0.7 | 8 | 8-0.5~0 | 0.9 | SKX-8 | 8 | 0.9 | 1.5 | 20 | 0.8 | CAD | RFQ |

| SETS-M4-10 | M4 | 0.7 | 10 | 8-0.5~0 | 0.9 | SKX-8 | 8 | 0.9 | 1.5 | 20 | 0.95 | CAD | RFQ |

| SETS-M4-12 | M4 | 0.7 | 12 | 8-0.5~0 | 0.9 | SKX-8 | 8 | 0.9 | 1.5 | 20 | 1.1 | CAD | RFQ |

| SETS-M4-16 | M4 | 0.7 | 16 | 8-0.5~0 | 0.9 | SKX-8 | 8 | 0.9 | 1.5 | 20 | 1.4 | CAD | RFQ |

| SETS-M4-20 | M4 | 0.7 | 20 | 8-0.5~0 | 0.9 | SKX-8 | 8 | 0.9 | 1.5 | 20 | 1.8 | CAD | RFQ |

| SETS-M4-25 | M4 | 0.7 | 25 | 8-0.5~0 | 0.9 | SKX-8 | 8 | 0.9 | 1.5 | 20 | 2.3 | CAD | RFQ |

| SETS-M5-8 | M5 | 0.8 | 8 | 9-0.5~0 | 1 | SKX-10 | 10 | 1 | 3.1 | 20 | 0.73 | CAD | RFQ |

| SETS-M5-10 | M5 | 0.8 | 10 | 9-0.5~0 | 1 | SKX-10 | 10 | 1 | 3.1 | 20 | 0.98 | CAD | RFQ |

| SETS-M5-12 | M5 | 0.8 | 12 | 9-0.5~0 | 1 | SKX-10 | 10 | 1 | 3.1 | 20 | 1.2 | CAD | RFQ |

| SETS-M5-16 | M5 | 0.8 | 16 | 9-0.5~0 | 1 | SKX-10 | 10 | 1 | 3.1 | 20 | 1.7 | CAD | RFQ |

| SETS-M5-20 | M5 | 0.8 | 20 | 9-0.5~0 | 1 | SKX-10 | 10 | 1 | 3.1 | 20 | 2.3 | CAD | RFQ |

| SETS-M5-25 | M5 | 0.8 | 25 | 9-0.5~0 | 1 | SKX-10 | 10 | 1 | 3.1 | 20 | 3.1 | CAD | RFQ |

| SETS-M5-30 | M5 | 0.8 | 30 | 9-0.5~0 | 1 | SKX-10 | 10 | 1 | 3.1 | 20 | 3.8 | CAD | RFQ |

| SETS-M6-8 | M6 | 1 | 8 | 12-0.6~0 | 1.2 | SKX-20 | 20 | 1.2 | 5.3 | 20 | 1.7 | CAD | RFQ |

| SETS-M6-10 | M6 | 1 | 10 | 12-0.6~0 | 1.2 | SKX-20 | 20 | 1.2 | 5.3 | 20 | 2.1 | CAD | RFQ |

| SETS-M6-12 | M6 | 1 | 12 | 12-0.6~0 | 1.2 | SKX-20 | 20 | 1.2 | 5.3 | 20 | 2.5 | CAD | RFQ |

| SETS-M6-16 | M6 | 1 | 16 | 12-0.6~0 | 1.2 | SKX-20 | 20 | 1.2 | 5.3 | 20 | 3.1 | CAD | RFQ |

| SETS-M6-20 | M6 | 1 | 20 | 12-0.6~0 | 1.2 | SKX-20 | 20 | 1.2 | 5.3 | 20 | 3.9 | CAD | RFQ |

| SETS-M6-25 | M6 | 1 | 25 | 12-0.6~0 | 1.2 | SKX-20 | 20 | 1.2 | 5.3 | 20 | 5 | CAD | RFQ |

| SETS-M6-30 | M6 | 1 | 30 | 12-0.6~0 | 1.2 | SKX-20 | 20 | 1.2 | 5.3 | 20 | 5.7 | CAD | RFQ |

| SETS-M6-35 | M6 | 1 | 35 | 12-0.6~0 | 1.2 | SKX-20 | 20 | 1.2 | 5.3 | 20 | 7.3 | CAD | RFQ |

| SETS-M6-40 | M6 | 1 | 40 | 12-0.6~0 | 1.2 | SKX-20 | 20 | 1.2 | 5.3 | 20 | 8.4 | CAD | RFQ |

Nabeya Bi-tech Kaisha

Customer Service

Please enter questions about customization and other product-related inquiries here.

Find the inquiry form here●When purchasing less volume than one full bag, a separate handling fee is charged. For details, see the Sold Separately Service.

Related Services

Material/Finish

| SETS | |

|---|---|

| Main Body | SUSXM7 (S.S. grade:A2) |

Application

Reducing the size of equipment and devicesCharacteristics

- Hexalobular socket*1 head cap screws with ultra-thin head.

- For space-saving of equipment/devices and applications with limited overhead space.

- Hexalobular socket shapes*1 are designed to withstand high tightening torque. ⇒Features of the Hexalobular Socket

- Install and remove with SKX Dedicated Wrench or SKXB Dedicated Bit and SRD Dedicated Magnetic Screwdriver together.

- Use the SKX-N hexalobular wrench for extremely limited access spaces for mounting and removing in tight spaces.

-

Also, products with special specifications such as ventilation holes, dimensions, shapes, materials, surface treatments, cleanroom washing & packaging are available.

⇒We can make a screw like this one

*1: The hexalobular shape is prescribed by JIS B 1015: 2008(ISO 10664: 2005)"Hexalobular internal driving feature for bolts and screws".