Specs/CAD

Unit : mm

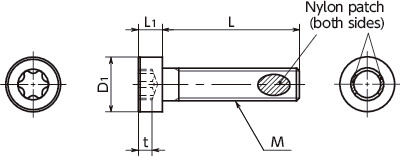

| Part Number | M (Coarse) Nominal of Thread |

Pitch | L | D1 | L1 | t | Hexalobular Socket No. |

Qty per Pack | Mass (g) |

CAD Download |

RFQ |

|---|---|---|---|---|---|---|---|---|---|---|---|

| SLTS-M2-4-ALK | M2 | 0.4 | 4 | 3.8 | 1.55 | 0.84 | 6 | 50 | 0.11 | CAD | RFQ |

| SLTS-M2-5-ALK | M2 | 0.4 | 5 | 3.8 | 1.55 | 0.84 | 6 | 50 | 0.13 | CAD | RFQ |

| SLTS-M2-6-ALK | M2 | 0.4 | 6 | 3.8 | 1.55 | 0.84 | 6 | 50 | 0.15 | CAD | RFQ |

| SLTS-M2-8-ALK | M2 | 0.4 | 8 | 3.8 | 1.55 | 0.84 | 6 | 50 | 0.19 | CAD | RFQ |

| SLTS-M2-10-ALK | M2 | 0.4 | 10 | 3.8 | 1.55 | 0.84 | 6 | 50 | 0.23 | CAD | RFQ |

| SLTS-M2.5-5-ALK | M2.5 | 0.45 | 5 | 4.5 | 1.85 | 0.91 | 8 | 50 | 0.26 | CAD | RFQ |

| SLTS-M2.5-6-ALK | M2.5 | 0.45 | 6 | 4.5 | 1.85 | 0.91 | 8 | 50 | 0.29 | CAD | RFQ |

| SLTS-M2.5-8-ALK | M2.5 | 0.45 | 8 | 4.5 | 1.85 | 0.91 | 8 | 50 | 0.35 | CAD | RFQ |

| SLTS-M2.5-10-ALK | M2.5 | 0.45 | 10 | 4.5 | 1.85 | 0.91 | 8 | 50 | 0.41 | CAD | RFQ |

| SLTS-M2.5-12-ALK | M2.5 | 0.45 | 12 | 4.5 | 1.85 | 0.91 | 8 | 50 | 0.47 | CAD | RFQ |

| SLTS-M3-6-ALK | M3 | 0.5 | 6 | 5.5 | 2.4 | 1.27 | 10 | 50 | 0.53 | CAD | RFQ |

| SLTS-M3-8-ALK | M3 | 0.5 | 8 | 5.5 | 2.4 | 1.27 | 10 | 50 | 0.62 | CAD | RFQ |

| SLTS-M3-10-ALK | M3 | 0.5 | 10 | 5.5 | 2.4 | 1.27 | 10 | 50 | 0.7 | CAD | RFQ |

| SLTS-M3-12-ALK | M3 | 0.5 | 12 | 5.5 | 2.4 | 1.27 | 10 | 50 | 0.78 | CAD | RFQ |

| SLTS-M3-16-ALK | M3 | 0.5 | 16 | 5.5 | 2.4 | 1.27 | 10 | 50 | 0.98 | CAD | RFQ |

| SLTS-M4-6-ALK | M4 | 0.7 | 6 | 7 | 3.1 | 1.66 | 20 | 50 | 1.1 | CAD | RFQ |

| SLTS-M4-8-ALK | M4 | 0.7 | 8 | 7 | 3.1 | 1.66 | 20 | 50 | 1.3 | CAD | RFQ |

| SLTS-M4-10-ALK | M4 | 0.7 | 10 | 7 | 3.1 | 1.66 | 20 | 50 | 1.4 | CAD | RFQ |

| SLTS-M4-12-ALK | M4 | 0.7 | 12 | 7 | 3.1 | 1.66 | 20 | 50 | 1.6 | CAD | RFQ |

| SLTS-M4-16-ALK | M4 | 0.7 | 16 | 7 | 3.1 | 1.66 | 20 | 50 | 1.9 | CAD | RFQ |

| SLTS-M4-20-ALK | M4 | 0.7 | 20 | 7 | 3.1 | 1.66 | 20 | 50 | 2.3 | CAD | RFQ |

| SLTS-M5-8-ALK | M5 | 0.8 | 8 | 8.5 | 3.65 | 1.91 | 25 | 50 | 1.8 | CAD | RFQ |

| SLTS-M5-10-ALK | M5 | 0.8 | 10 | 8.5 | 3.65 | 1.91 | 25 | 50 | 2 | CAD | RFQ |

| SLTS-M5-12-ALK | M5 | 0.8 | 12 | 8.5 | 3.65 | 1.91 | 25 | 50 | 2.3 | CAD | RFQ |

| SLTS-M5-16-ALK | M5 | 0.8 | 16 | 8.5 | 3.65 | 1.91 | 25 | 50 | 2.8 | CAD | RFQ |

| SLTS-M5-20-ALK | M5 | 0.8 | 20 | 8.5 | 3.65 | 1.91 | 25 | 50 | 3.3 | CAD | RFQ |

| SLTS-M5-25-ALK | M5 | 0.8 | 25 | 8.5 | 3.65 | 1.91 | 25 | 50 | 4.1 | CAD | RFQ |

| SLTS-M6-8-ALK | M6 | 1 | 8 | 10 | 4.4 | 2.29 | 30 | 20 | 3.1 | CAD | RFQ |

| SLTS-M6-10-ALK | M6 | 1 | 10 | 10 | 4.4 | 2.29 | 30 | 20 | 3.5 | CAD | RFQ |

| SLTS-M6-12-ALK | M6 | 1 | 12 | 10 | 4.4 | 2.29 | 30 | 20 | 3.8 | CAD | RFQ |

| SLTS-M6-16-ALK | M6 | 1 | 16 | 10 | 4.4 | 2.29 | 30 | 20 | 4.5 | CAD | RFQ |

| SLTS-M6-20-ALK | M6 | 1 | 20 | 10 | 4.4 | 2.29 | 30 | 20 | 5.3 | CAD | RFQ |

| SLTS-M6-25-ALK | M6 | 1 | 25 | 10 | 4.4 | 2.29 | 30 | 20 | 6.4 | CAD | RFQ |

| SLTS-M6-30-ALK | M6 | 1 | 30 | 10 | 4.4 | 2.29 | 30 | 20 | 7.1 | CAD | RFQ |

Nabeya Bi-tech Kaisha

Customer Service

Please enter questions about customization and other product-related inquiries here.

Find the inquiry form here● When purchasing less volume than one full bag, a separate handling fee is charged. For details, see the Sold Separately Service.

Related Services

Material/Finish

| SLTS-ALK | |

|---|---|

| Main Body | SUSXM7 (Equivalent to SUS304) |

| Nylon Patch | Nylon 11 |

| Strength Class | A2 - 50 |

Application

Reducing the size of equipment and devicesPrevention of damage to screw heads

Reliable tightening

Screw return and fallout prevented

Characteristics

- Low profile hexalobular socket*1 cap screws with nylon patch.

- Hexalobular socket shapes are designed to withstand high tightening torque compared to cross-recesses. ⇒Features of the Hexalobular Socket

- Recesses are unlikely to be damaged due to tightening, allowing safe and secure tightening to be performed.

- For space-saving of equipment/devices and applications with limited overhead space.

- The friction of the nylon adhered to the thread suppresses the return rotation of the thread.

- Even if the tightening force is lost, the return rotation is suppressed, preventing the screws from falling off.

- The heat resistant temperature of the nylon patch is 120°C.

*1: The hexalobular shape is prescribed by JIS B 1015: 2008(ISO 10664: 2005)"Hexalobular internal driving feature for bolts and screws".