Specs/CAD

Unit : mm

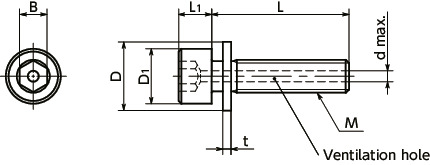

| Part Number | M (Coarse) Nominal of Thread |

Pitch | L | D1 | D | L1 | B | t | d max. | Qty per Pack | Mass (g) |

CAD Download |

RFQ |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SVSI1S-M3-5 | M3 | 0.5 | 5 | 5.5 | 7 | 3 | 2.5 | 0.5 | 1.2 | 10 | 0.79 | CAD | RFQ |

| SVSI1S-M3-6 | M3 | 0.5 | 6 | 5.5 | 7 | 3 | 2.5 | 0.5 | 1.2 | 10 | 0.83 | CAD | RFQ |

| SVSI1S-M3-8 | M3 | 0.5 | 8 | 5.5 | 7 | 3 | 2.5 | 0.5 | 1.2 | 10 | 0.92 | CAD | RFQ |

| SVSI1S-M3-10 | M3 | 0.5 | 10 | 5.5 | 7 | 3 | 2.5 | 0.5 | 1.2 | 10 | 1 | CAD | RFQ |

| SVSI1S-M3-12 | M3 | 0.5 | 12 | 5.5 | 7 | 3 | 2.5 | 0.5 | 1.2 | 10 | 1.1 | CAD | RFQ |

| SVSI1S-M3-16 | M3 | 0.5 | 16 | 5.5 | 7 | 3 | 2.5 | 0.5 | 1.2 | 10 | 1.3 | CAD | RFQ |

| SVSI1S-M4-5 | M4 | 0.7 | 5 | 7 | 9 | 4 | 3 | 0.8 | 1.5 | 10 | 1.7 | CAD | RFQ |

| SVSI1S-M4-6 | M4 | 0.7 | 6 | 7 | 9 | 4 | 3 | 0.8 | 1.5 | 10 | 1.8 | CAD | RFQ |

| SVSI1S-M4-8 | M4 | 0.7 | 8 | 7 | 9 | 4 | 3 | 0.8 | 1.5 | 10 | 2 | CAD | RFQ |

| SVSI1S-M4-10 | M4 | 0.7 | 10 | 7 | 9 | 4 | 3 | 0.8 | 1.5 | 10 | 2.1 | CAD | RFQ |

| SVSI1S-M4-12 | M4 | 0.7 | 12 | 7 | 9 | 4 | 3 | 0.8 | 1.5 | 10 | 2.3 | CAD | RFQ |

| SVSI1S-M4-16 | M4 | 0.7 | 16 | 7 | 9 | 4 | 3 | 0.8 | 1.5 | 10 | 2.6 | CAD | RFQ |

| SVSI1S-M4-20 | M4 | 0.7 | 20 | 7 | 9 | 4 | 3 | 0.8 | 1.5 | 10 | 3 | CAD | RFQ |

| SVSI1S-M4-25 | M4 | 0.7 | 25 | 7 | 9 | 4 | 3 | 0.8 | 1.5 | 10 | 3.5 | CAD | RFQ |

| SVSI1S-M4-30 | M4 | 0.7 | 30 | 7 | 9 | 4 | 3 | 0.8 | 1.5 | 10 | 4 | CAD | RFQ |

| SVSI1S-M4-35 | M4 | 0.7 | 35 | 7 | 9 | 4 | 3 | 0.8 | 1.5 | 10 | 4.5 | CAD | RFQ |

| SVSI1S-M5-6 | M5 | 0.8 | 6 | 8.5 | 10 | 5 | 4 | 1 | 1.5 | 10 | 2.6 | CAD | RFQ |

| SVSI1S-M5-8 | M5 | 0.8 | 8 | 8.5 | 10 | 5 | 4 | 1 | 1.5 | 10 | 2.9 | CAD | RFQ |

| SVSI1S-M5-10 | M5 | 0.8 | 10 | 8.5 | 10 | 5 | 4 | 1 | 1.5 | 10 | 3.1 | CAD | RFQ |

| SVSI1S-M5-12 | M5 | 0.8 | 12 | 8.5 | 10 | 5 | 4 | 1 | 1.5 | 10 | 3.4 | CAD | RFQ |

| SVSI1S-M5-16 | M5 | 0.8 | 16 | 8.5 | 10 | 5 | 4 | 1 | 1.5 | 10 | 3.9 | CAD | RFQ |

| SVSI1S-M5-20 | M5 | 0.8 | 20 | 8.5 | 10 | 5 | 4 | 1 | 1.5 | 10 | 4.4 | CAD | RFQ |

| SVSI1S-M5-25 | M5 | 0.8 | 25 | 8.5 | 10 | 5 | 4 | 1 | 1.5 | 10 | 5.2 | CAD | RFQ |

| SVSI1S-M5-30 | M5 | 0.8 | 30 | 8.5 | 10 | 5 | 4 | 1 | 1.5 | 10 | 6 | CAD | RFQ |

| SVSI1S-M5-35 | M5 | 0.8 | 35 | 8.5 | 10 | 5 | 4 | 1 | 1.5 | 10 | 6.7 | CAD | RFQ |

| SVSI1S-M5-40 | M5 | 0.8 | 40 | 8.5 | 10 | 5 | 4 | 1 | 1.5 | 10 | 7.5 | CAD | RFQ |

| SVSI1S-M6-8 | M6 | 1 | 8 | 10 | 12.5 | 6 | 5 | 1.5 | 2 | 10 | 5.4 | CAD | RFQ |

| SVSI1S-M6-10 | M6 | 1 | 10 | 10 | 12.5 | 6 | 5 | 1.5 | 2 | 10 | 5.8 | CAD | RFQ |

| SVSI1S-M6-12 | M6 | 1 | 12 | 10 | 12.5 | 6 | 5 | 1.5 | 2 | 10 | 6.2 | CAD | RFQ |

| SVSI1S-M6-16 | M6 | 1 | 16 | 10 | 12.5 | 6 | 5 | 1.5 | 2 | 10 | 6.9 | CAD | RFQ |

| SVSI1S-M6-20 | M6 | 1 | 20 | 10 | 12.5 | 6 | 5 | 1.5 | 2 | 10 | 7.6 | CAD | RFQ |

| SVSI1S-M6-25 | M6 | 1 | 25 | 10 | 12.5 | 6 | 5 | 1.5 | 2 | 10 | 8.7 | CAD | RFQ |

| SVSI1S-M6-30 | M6 | 1 | 30 | 10 | 12.5 | 6 | 5 | 1.5 | 2 | 10 | 9.4 | CAD | RFQ |

| SVSI1S-M6-35 | M6 | 1 | 35 | 10 | 12.5 | 6 | 5 | 1.5 | 2 | 10 | 11 | CAD | RFQ |

| SVSI1S-M6-40 | M6 | 1 | 40 | 10 | 12.5 | 6 | 5 | 1.5 | 2 | 10 | 12 | CAD | RFQ |

| SVSI1S-M6-45 | M6 | 1 | 45 | 10 | 12.5 | 6 | 5 | 1.5 | 2 | 10 | 13 | CAD | RFQ |

Nabeya Bi-tech Kaisha

Customer Service

Please enter questions about customization and other product-related inquiries here.

Find the inquiry form here● When purchasing less volume than one full bag, a separate handling fee is charged. For details, see the Sold Separately Service.

Related Services

Material/Finish

| SVSI1S | |

|---|---|

| Screw Body | SUSXM7 (Equivalent to SUS304) |

| Screw Body Strength Class | A2 - 70 |

| Plain Washer | SUS304 |

Application

Semiconductor manufacturing equipment / Equipment and device structures / Offshore instruments / General industrial machinesCharacteristics

- The ventilation hole easily releases gas trapped in the screw holes of equipment and machines, and supports vacuum drawing of vacuum devices.

- Ventilation holes are machined using a method with minimal effect on metallic structures. Brittle fracture and outgassing during use in vacuum environments are prevented.

- Plain washers are integrated into the screws, preventing concerns about fallout issues. (Washer abbreviation: I=1)

- When using a washer in spot facing, workability is improved because the bolt and washer can be mounted and removed at the same time.

- Washer mounting work is not required. Cleanroom work in gloves is easier.

- Cleanroom wash/cleanroom packing provided.⇒Cleanroom Wash / Cleanroom Packing Service