Specs/CAD

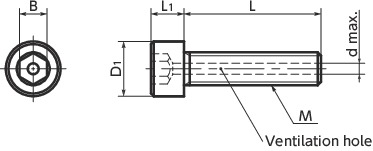

Unit : mm

| Part Number | M (Coarse) Nominal of Thread |

Pitch | L | D1 | L1 | B | d max. |

Mass (g) |

CAD Download |

RFQ |

|---|---|---|---|---|---|---|---|---|---|---|

| SVSL-M3-6-PN | M3 | 0.5 | 6 | 5.5 | 3 | 2.5 | 1.2 | 0.64 | CAD | RFQ |

| SVSL-M3-8-PN | M3 | 0.5 | 8 | 5.5 | 3 | 2.5 | 1.2 | 0.7 | CAD | RFQ |

| SVSL-M3-10-PN | M3 | 0.5 | 10 | 5.5 | 3 | 2.5 | 1.2 | 0.76 | CAD | RFQ |

| SVSL-M3-12-PN | M3 | 0.5 | 12 | 5.5 | 3 | 2.5 | 1.2 | 0.81 | CAD | RFQ |

| SVSL-M4-8-PN | M4 | 0.7 | 8 | 7 | 4 | 3 | 1.5 | 1.5 | CAD | RFQ |

| SVSL-M4-10-PN | M4 | 0.7 | 10 | 7 | 4 | 3 | 1.5 | 1.6 | CAD | RFQ |

| SVSL-M4-12-PN | M4 | 0.7 | 12 | 7 | 4 | 3 | 1.5 | 1.8 | CAD | RFQ |

| SVSL-M4-16-PN | M4 | 0.7 | 16 | 7 | 4 | 3 | 1.5 | 2 | CAD | RFQ |

| SVSL-M4-20-PN | M4 | 0.7 | 20 | 7 | 4 | 3 | 1.5 | 2.3 | CAD | RFQ |

| SVSL-M5-8-PN | M5 | 0.8 | 8 | 8.5 | 5 | 4 | 1.5 | 2.3 | CAD | RFQ |

| SVSL-M5-10-PN | M5 | 0.8 | 10 | 8.5 | 5 | 4 | 1.5 | 2.5 | CAD | RFQ |

| SVSL-M5-12-PN | M5 | 0.8 | 12 | 8.5 | 5 | 4 | 1.5 | 2.8 | CAD | RFQ |

| SVSL-M5-16-PN | M5 | 0.8 | 16 | 8.5 | 5 | 4 | 1.5 | 3.2 | CAD | RFQ |

| SVSL-M5-20-PN | M5 | 0.8 | 20 | 8.5 | 5 | 4 | 1.5 | 3.6 | CAD | RFQ |

| SVSL-M6-10-PN | M6 | 1 | 10 | 10 | 6 | 5 | 2 | 4.4 | CAD | RFQ |

| SVSL-M6-12-PN | M6 | 1 | 12 | 10 | 6 | 5 | 2 | 4.7 | CAD | RFQ |

| SVSL-M6-16-PN | M6 | 1 | 16 | 10 | 6 | 5 | 2 | 5.2 | CAD | RFQ |

| SVSL-M6-20-PN | M6 | 1 | 20 | 10 | 6 | 5 | 2 | 5.8 | CAD | RFQ |

| SVSL-M6-25-PN | M6 | 1 | 25 | 10 | 6 | 5 | 2 | 6.7 | CAD | RFQ |

| SVSL-M6-30-PN | M6 | 1 | 30 | 10 | 6 | 5 | 2 | 7.3 | CAD | RFQ |

| SVSL-M8-16-PN | M8 | 1.25 | 16 | 13 | 8 | 6 | 2 | 11 | CAD | RFQ |

| SVSL-M8-20-PN | M8 | 1.25 | 20 | 13 | 8 | 6 | 2 | 12 | CAD | RFQ |

| SVSL-M8-25-PN | M8 | 1.25 | 25 | 13 | 8 | 6 | 2 | 14 | CAD | RFQ |

| SVSL-M8-30-PN | M8 | 1.25 | 30 | 13 | 8 | 6 | 2 | 16 | CAD | RFQ |

| SVSL-M8-35-PN | M8 | 1.25 | 35 | 13 | 8 | 6 | 2 | 18 | CAD | RFQ |

● Batch cleanroom packing is provided for orders containing multiple items of the same size.

Nabeya Bi-tech Kaisha

Customer Service

Please enter questions about customization and other product-related inquiries here.

Find the inquiry form hereRelated Services

Material/Finish

| SVSL-PN | |

|---|---|

| Main Body | SUS316L Surface hardening treatment |

| Strength Class | A4-70 |

Application

Seizing PreventionVacuum devices / Vacuum chambers / FPD production equipment /

Semiconductor devices / Electron microscopes / Food industry machines

Characteristics

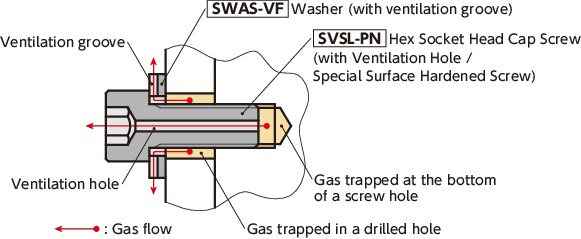

- The ventilation hole easily releases gas trapped in the screw holes of equipment and machines, and supports vacuum drawing of vacuum devices.

- Hardening the screw surface prevents screw seizing / sticking.

- Unlike platings or coatings, there is nothing adhering to the surface, eliminating concerns about contamination due to stripping during tightening.

- Suitable for prevention of seizing in environments where lubrication cannot be used.

- Cleanroom washed and packed. ⇒Cleanroom Wash / Cleanroom Packing Service

- For details on the features of the special surface hardened treatment, please refer to the "Advantages of Special Surface Hardened Screws".

Usage Example

Gas trapped at the bottom of a screw hole is released through SVSL-PN, and gas trapped in a drilled hole is released through SWAS-VF(SWAS-VFSWAS-VF-PC).

Precautions for Use

May have lower corrosion resistance than general SUS316L.We recommend performing a test under the same usage conditions as in actual usage in advance.