Specs/CAD

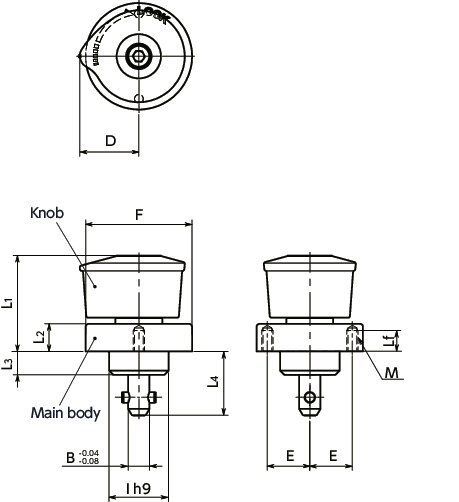

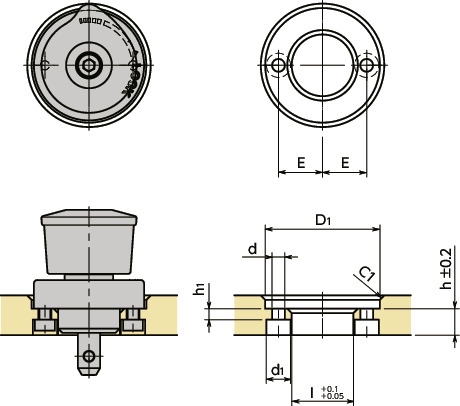

Unit : mm

| Part Number | F | L1 | L3 | I | L2 | D | M (Coarse) Nominal of Thread |

Pitch | Lf | E | B | L4 | Applicable Plate Thickness | Repeated Positioning Accuracy | Clamping Force *1 (N) |

Mass (g) |

Price (USD) |

CAD Download |

Add to Cart | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Without [[NQTS-SPCR]] | With [[NQTS-SPCR]] | |||||||||||||||||||

| NQTS-5-BK | 25 | 22.4 | 5.5 | 14 | 6.5 | 13.9 | M2.5 | 0.45 | 4 | 10 | 5 | 15.1 | 6~10 | 3~6 | ±0.1 | 60 | 39 | 94.92 | CAD | Cart |

| NQTS-8-BK | 34 | 28.4 | 5.5 | 18 | 10 | 18.5 | M3 | 0.5 | 6 | 13 | 8 | 16.5 | 6~14 | 3~6 | ±0.1 | 90 | 94 | 97.26 | CAD | Cart |

| NQTS-8-L-BK | 34 | 28.4 | 5.5 | 18 | 10 | 18.5 | M3 | 0.5 | 6 | 13 | 8 | 22.5 | 12~20 | - | ±0.1 | 90 | 98 | 97.26 | CAD | Cart |

*1: Clamping force is the maximum allowable load retaining the mounting plate clearance within 0.1mm against tensile load.

Characteristics

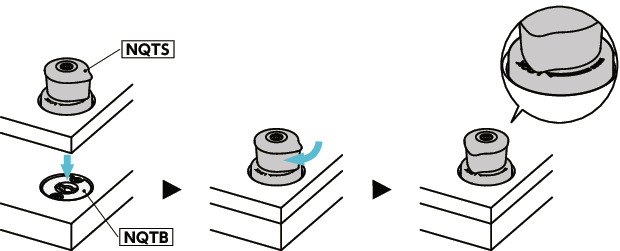

- In combination with the dedicated cam base, jigs can be easily mounted and removed without tools.

- Just rotate the knob 90°to clamp and unclamp: ideal for repetitive work.

- The knob is reverse-tapered to a hand-friendly round shape, with laser engraving on the main body enabling corrosion resistance to be retained.

- The knob projection and laser engraving make the clamping status clear at a glance.

- The knob operation part has passed 50,000 operation tests. With excellent endurance, it reduces part replacement frequency.

- Two hex socket head cap screws for mounting are provided.

- For mounting to plates from 3mm to less than 6mm, use the dedicated spacer NQTS-SPCR.

Material/Finish

| NQTS | |

|---|---|

| Main Body | SUS303 |

| Knob | Glass Fiber Reinforced Nylon |

| Hex Socket Head Cap Screw | Stainless Steel |

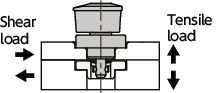

Max. Allowable Load

| Part Number | Max. Allowable Shear Load (N) | Max. Allowable Tensile Load (N) |

|---|---|---|

| NQTS-5-BK | 1800 | 1200 |

| NQTS-8-BK | 3200 | 2600 |

| NQTS-8-L-BK | 3200 | 2600 |

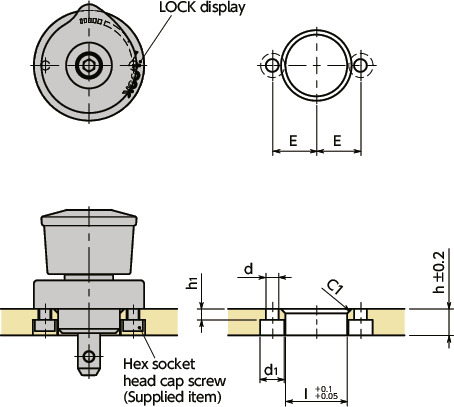

Mounting

The LOCK display is laser engraved on a straight line from the mounting hole. Set the LOCK display and mounting hole position with attention to workability.When the plate thickness is from 3mm to less than 6mm, refer to NQTS-SPCR mounting.

Unit : mm

| Part Number | Applicable Plate Thickness | I | h | E | d | d1 | h1 |

|---|---|---|---|---|---|---|---|

| NQTS-5-BK | 6 | 14 | 6 | 10 | 2.9 | 5.5 | 2.5 |

| NQTS-8-BK | 6 | 18 | 6 | 13 | 3.4 | 6.5 | 2.5 |

| NQTS-8-L-BK | 12 | 18 | 12 | 13 | 3.4 | 6.5 | 2.5 |

Unit : mm

| Part Number | Applicable Plate Thickness | I | D1 | h | E | d | d1 | h1 |

|---|---|---|---|---|---|---|---|---|

| NQTS-5-BK | 6~10 | 14 | 26 | 6 | 10 | 2.9 | 5.5 | 2.5 |

| NQTS-8-BK | 6~14 | 18 | 35 | 6 | 13 | 3.4 | 6.5 | 2.5 |

| NQTS-8-L-BK | 12~20 | 18 | 35 | 12 | 13 | 3.4 | 6.5 | 2.5 |

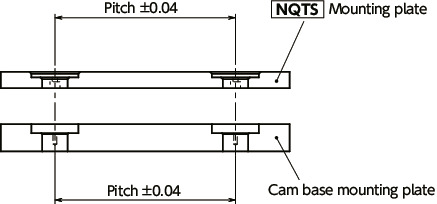

Pitch Precision Between Holes

The pitch tolerance of the NQTS mounting plate and the cam base mounting plate should be ±0.04mm or below.

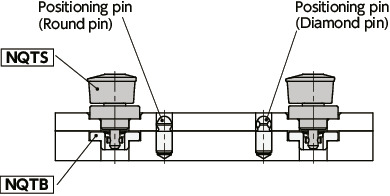

Repeated Positioning Accuracy

Repeated positioning accuracy is ±0.1mm. When even higher-precision positioning is required, prepare a positioning pin suited to the application.

Usage Example

In combination with dedicated cam base NQTB, etc.