Hints for Correctly Using NBK Products

The video is an example using SSC (SSC). You can perform the same operation using this product.

Specs/CAD

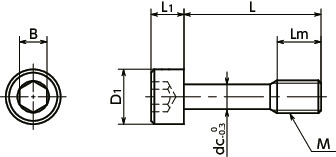

Unit : mm

| Part Number | M (Coarse) Nominal of Thread |

Pitch | L | Lm | D1 | L1 | B | dc | Mass (g) |

Price (USD) |

CAD Download |

QTY (Piece) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SSC-M3-4-UCL | M3 | 0.5 | 4 | 2 | 5.5 | 3 | 2.5 | 2.2 | 0.6 | 3.44 | CAD | Cart |

| SSC-M3-6-UCL | M3 | 0.5 | 6 | 2 | 5.5 | 3 | 2.5 | 2.2 | 0.7 | 3.44 | CAD | Cart |

| SSC-M3-8-UCL | M3 | 0.5 | 8 | 4 | 5.5 | 3 | 2.5 | 2.2 | 0.8 | 3.44 | CAD | Cart |

| SSC-M3-10-UCL | M3 | 0.5 | 10 | 4 | 5.5 | 3 | 2.5 | 2.2 | 0.88 | 3.44 | CAD | Cart |

| SSC-M3-12-UCL | M3 | 0.5 | 12 | 4 | 5.5 | 3 | 2.5 | 2.2 | 0.96 | 3.44 | CAD | Cart |

| SSC-M3-16-UCL | M3 | 0.5 | 16 | 4 | 5.5 | 3 | 2.5 | 2.2 | 1.2 | 3.44 | CAD | Cart |

| SSC-M4-6-UCL | M4 | 0.7 | 6 | 3 | 7 | 4 | 3 | 3 | 1.4 | 2.81 | CAD | Cart |

| SSC-M4-8-UCL | M4 | 0.7 | 8 | 3 | 7 | 4 | 3 | 3 | 1.6 | 2.81 | CAD | Cart |

| SSC-M4-10-UCL | M4 | 0.7 | 10 | 5 | 7 | 4 | 3 | 3 | 1.8 | 2.81 | CAD | Cart |

| SSC-M4-12-UCL | M4 | 0.7 | 12 | 5 | 7 | 4 | 3 | 3 | 2 | 2.81 | CAD | Cart |

| SSC-M4-16-UCL | M4 | 0.7 | 16 | 5 | 7 | 4 | 3 | 3 | 2.3 | 2.81 | CAD | Cart |

| SSC-M4-20-UCL | M4 | 0.7 | 20 | 5 | 7 | 4 | 3 | 3 | 2.7 | 2.81 | CAD | Cart |

| SSC-M5-8-UCL | M5 | 0.8 | 8 | 4 | 8.5 | 5 | 4 | 3.9 | 2.5 | 3.13 | CAD | Cart |

| SSC-M5-10-UCL | M5 | 0.8 | 10 | 4 | 8.5 | 5 | 4 | 3.9 | 2.7 | 3.13 | CAD | Cart |

| SSC-M5-12-UCL | M5 | 0.8 | 12 | 6 | 8.5 | 5 | 4 | 3.9 | 3 | 3.13 | CAD | Cart |

| SSC-M5-16-UCL | M5 | 0.8 | 16 | 6 | 8.5 | 5 | 4 | 3.9 | 3.5 | 3.13 | CAD | Cart |

| SSC-M5-20-UCL | M5 | 0.8 | 20 | 6 | 8.5 | 5 | 4 | 3.9 | 4 | 3.13 | CAD | Cart |

| SSC-M5-25-UCL | M5 | 0.8 | 25 | 6 | 8.5 | 5 | 4 | 3.9 | 4.8 | 3.13 | CAD | Cart |

| SSC-M6-8-UCL | M6 | 1 | 8 | 4 | 10 | 6 | 5 | 4.5 | 4.4 | 3.44 | CAD | Cart |

| SSC-M6-10-UCL | M6 | 1 | 10 | 4 | 10 | 6 | 5 | 4.5 | 4.7 | 3.44 | CAD | Cart |

| SSC-M6-12-UCL | M6 | 1 | 12 | 8 | 10 | 6 | 5 | 4.5 | 5.1 | 3.44 | CAD | Cart |

| SSC-M6-16-UCL | M6 | 1 | 16 | 8 | 10 | 6 | 5 | 4.5 | 5.8 | 3.44 | CAD | Cart |

| SSC-M6-20-UCL | M6 | 1 | 20 | 8 | 10 | 6 | 5 | 4.5 | 6.5 | 3.44 | CAD | Cart |

| SSC-M6-25-UCL | M6 | 1 | 25 | 8 | 10 | 6 | 5 | 4.5 | 7.6 | 3.44 | CAD | Cart |

| SSC-M6-30-UCL | M6 | 1 | 30 | 8 | 10 | 6 | 5 | 4.5 | 8.3 | 3.44 | CAD | Cart |

| SSC-M8-8-UCL | M8 | 1.25 | 8 | 5 | 13 | 8 | 6 | 6.3 | 9 | 5.31 | CAD | Cart |

| SSC-M8-10-UCL | M8 | 1.25 | 10 | 5 | 13 | 8 | 6 | 6.3 | 10 | 4.69 | CAD | Cart |

| SSC-M8-12-UCL | M8 | 1.25 | 12 | 5 | 13 | 8 | 6 | 6.3 | 11 | 4.69 | CAD | Cart |

| SSC-M8-16-UCL | M8 | 1.25 | 16 | 10 | 13 | 8 | 6 | 6.3 | 12 | 4.69 | CAD | Cart |

| SSC-M8-20-UCL | M8 | 1.25 | 20 | 10 | 13 | 8 | 6 | 6.3 | 13 | 4.69 | CAD | Cart |

| SSC-M8-25-UCL | M8 | 1.25 | 25 | 10 | 13 | 8 | 6 | 6.3 | 15 | 4.69 | CAD | Cart |

| SSC-M8-30-UCL | M8 | 1.25 | 30 | 10 | 13 | 8 | 6 | 6.3 | 17 | 4.69 | CAD | Cart |

| SSC-M8-35-UCL | M8 | 1.25 | 35 | 10 | 13 | 8 | 6 | 6.3 | 19 | 4.69 | CAD | Cart |

| SSC-M8-40-UCL | M8 | 1.25 | 40 | 10 | 13 | 8 | 6 | 6.3 | 21 | 5.00 | CAD | Cart |

● Batch cleanroom packing is provided for orders containing multiple items of the same size.

Nabeya Bi-tech Kaisha

Customer Service

Please enter questions about customization and other product-related inquiries here.

Find the inquiry form hereMaterial/Finish

| SSC-UCL | |

|---|---|

| Main Body | SUSXM7 (Equivalent to SUS304) USC Cleaning |

| Strength Class | A2 - 70 |

Application

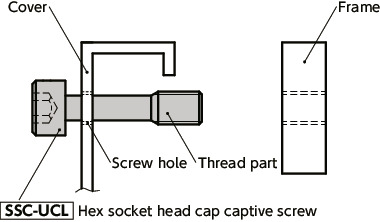

For fixing protective covers and maintenance coversCE Marking compatible

Machine tools / Food machinery / Electrical and electronic equipment

Characteristics

- Prevents fallout and loss of the screw. They are intended to fix protective and inspection covers that are frequently installed and removed.

- For CE Marking compatibility. ⇒Use the NBK Captive Screw Series to be comply with CE

- Cleanroom washed (ultrasonic cleaning) and cleanroom packaged. ⇒Cleanroom Wash / Cleanroom Packing Service

- For parts embedded in FPD production equipment, semiconductor manufacturing devices, medical equipment, or food machinery, or used in cleanrooms.

Precautions for Use

- Screw hole inner diameter on the cover side shall be at least the dc dimension.

- The cover thickness should be 0.8 mm or above.

Installation Example

Make a screw hole in the cover, and then pass the SSC-UCL thread part through it. Even when the screw is removed from the frame, SSC-UCL does not fall out of the cover because the SSC-UCL thread part catches on the cover screw hole.