Specs/CAD

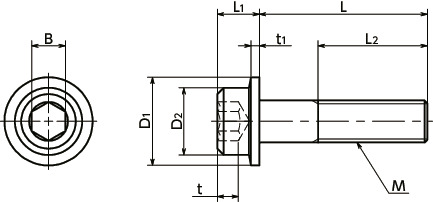

Unit : mm

| Part Number | M (Coarse) Nominal of Thread |

Pitch | L | D1 | D2 | L1 | L2 | B | t | t1 | Mass (g) |

CAD Download |

RFQ |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SFSS-M4-6-RY | M4 | 0.7 | 6 | 9 | 7 | 4 | Full Thread | 3 | 2 | 0.8 | 1.5 | CAD | RFQ |

| SFSS-M4-8-RY | M4 | 0.7 | 8 | 9 | 7 | 4 | Full Thread | 3 | 2 | 0.8 | 1.7 | CAD | RFQ |

| SFSS-M4-10-RY | M4 | 0.7 | 10 | 9 | 7 | 4 | Full Thread | 3 | 2 | 0.8 | 1.8 | CAD | RFQ |

| SFSS-M4-12-RY | M4 | 0.7 | 12 | 9 | 7 | 4 | Full Thread | 3 | 2 | 0.8 | 2 | CAD | RFQ |

| SFSS-M4-16-RY | M4 | 0.7 | 16 | 9 | 7 | 4 | Full Thread | 3 | 2 | 0.8 | 2.2 | CAD | RFQ |

| SFSS-M4-20-RY | M4 | 0.7 | 20 | 9 | 7 | 4 | Full Thread | 3 | 2 | 0.8 | 2.6 | CAD | RFQ |

| SFSS-M5-8-RY | M5 | 0.8 | 8 | 11 | 8.5 | 5 | Full Thread | 4 | 2.5 | 1 | 2.9 | CAD | RFQ |

| SFSS-M5-10-RY | M5 | 0.8 | 10 | 11 | 8.5 | 5 | Full Thread | 4 | 2.5 | 1 | 3.2 | CAD | RFQ |

| SFSS-M5-12-RY | M5 | 0.8 | 12 | 11 | 8.5 | 5 | Full Thread | 4 | 2.5 | 1 | 3.4 | CAD | RFQ |

| SFSS-M5-16-RY | M5 | 0.8 | 16 | 11 | 8.5 | 5 | Full Thread | 4 | 2.5 | 1 | 3.9 | CAD | RFQ |

| SFSS-M5-20-RY | M5 | 0.8 | 20 | 11 | 8.5 | 5 | Full Thread | 4 | 2.5 | 1 | 4.4 | CAD | RFQ |

| SFSS-M5-25-RY | M5 | 0.8 | 25 | 11 | 8.5 | 5 | 16 | 4 | 2.5 | 1 | 5.2 | CAD | RFQ |

| SFSS-M6-10-RY | M6 | 1 | 10 | 12.5 | 10 | 6 | Full Thread | 5 | 3 | 1.6 | 4.9 | CAD | RFQ |

| SFSS-M6-12-RY | M6 | 1 | 12 | 12.5 | 10 | 6 | Full Thread | 5 | 3 | 1.6 | 5.3 | CAD | RFQ |

| SFSS-M6-16-RY | M6 | 1 | 16 | 12.5 | 10 | 6 | Full Thread | 5 | 3 | 1.6 | 6 | CAD | RFQ |

| SFSS-M6-20-RY | M6 | 1 | 20 | 12.5 | 10 | 6 | Full Thread | 5 | 3 | 1.6 | 6.6 | CAD | RFQ |

| SFSS-M6-25-RY | M6 | 1 | 25 | 12.5 | 10 | 6 | Full Thread | 5 | 3 | 1.6 | 7.5 | CAD | RFQ |

| SFSS-M8-12-RY | M8 | 1.25 | 12 | 17 | 13 | 8 | Full Thread | 6 | 4 | 1.6 | 11 | CAD | RFQ |

| SFSS-M8-16-RY | M8 | 1.25 | 16 | 17 | 13 | 8 | Full Thread | 6 | 4 | 1.6 | 13 | CAD | RFQ |

| SFSS-M8-20-RY | M8 | 1.25 | 20 | 17 | 13 | 8 | Full Thread | 6 | 4 | 1.6 | 14 | CAD | RFQ |

| SFSS-M8-25-RY | M8 | 1.25 | 25 | 17 | 13 | 8 | Full Thread | 6 | 4 | 1.6 | 15 | CAD | RFQ |

| SFSS-M8-30-RY | M8 | 1.25 | 30 | 17 | 13 | 8 | Full Thread | 6 | 4 | 1.6 | 17 | CAD | RFQ |

Nabeya Bi-tech Kaisha

Customer Service

Please enter questions about customization and other product-related inquiries here.

Find the inquiry form hereRelated Services

Material/Finish

| SFSS-RY | |

|---|---|

| Main Body | SUSXM7 (Equivalent to SUS304) Low Temperature Black Chrome Treatment |

| Strength Class | A2 - 70 |

Application

Seizing preventionAnti-reflection

Optical equipment / FPD production equipment / Semiconductor manufacturing equipment

Characteristics

- Because the bearing surface is larger due to the head part flange, the pressure on the fastened material is dispersed compared to normal hex socket head cap screws, making bearing surfaces less likely to sink. Also, the bearing surface can be ensured even with large drilled hole diameters.

- Washer mounting work is not required, reducing the parts needed.

- Washerless design makes it ideal for automated screw fastening by robots.

- Corrosion resistance, chemical resistance, and abrasion resistance are excellent.

- Low outgas quantity, usable in vacuum environments.

- Excellent lubrication property. Suitable for preventing seizing.

- Spectral reflectance 1.5% or below. For optical equipment and other applications requiring anti-reflection.⇒The Features of Screws with Special Surface Treatment

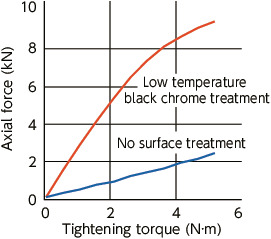

Tightening Property (Reference)

Reference data for Hex Socket Head Cap Screw - SUSXM7 - Low Temperature Black Chrome Treatment SNSS-M5-25-RY.⇒The Features of Screws with Special Surface Treatment